|

Nasslaufende Ortlinghaus Kupp-lungen und Bremsen in Warm-schmieden und Walzwerken |

Weiterentwicklung auf die Verwendbarkeit von schwer entflammbaren Schmierstoffen |

|

|

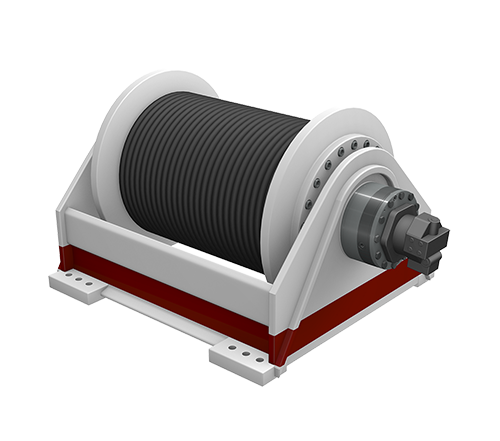

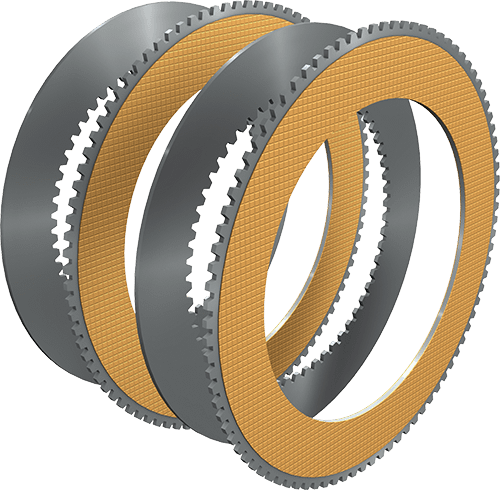

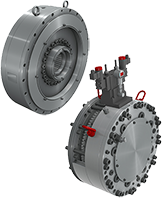

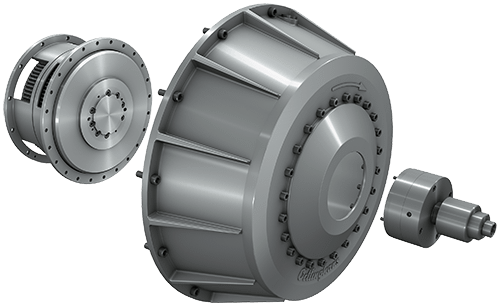

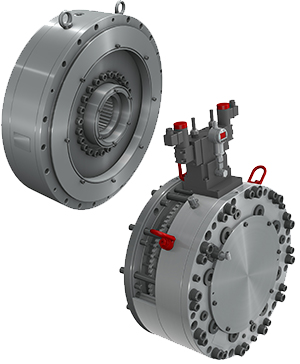

Seit Jahrzehnten verrichten nass-laufende Ortlinghaus Kupplungen, Bremsen und Kupplungs-Brems-Kombinationen auch in Warm-schmieden und Walzwerken zuverlässig ihren Dienst. Bei diesen Kupplungen und Bremsen werden die Kontaktflächen der Reibelemente permanent mit Schmier- und Kühlöl versorgt. Die in solchen Nasslaufsystemen eingesetzten Sinterlamellen basieren auf bronzehaltigen Reibwerkstoffen, welche die Ölmoleküle aus dem konstanten Ölstrom in ihren Oberflächen einlagern. Abb. 1: Nasslaufendes Lamellenpaket mit Original Ortlinghaus Sinterlamellen Dadurch entsteht bei Aktivierung der Kupplung so gut wie kein Abrieb in den Reibbelägen, woraus weitestgehend verschleißfreie Kupplungs- und Bremssysteme resultieren. |

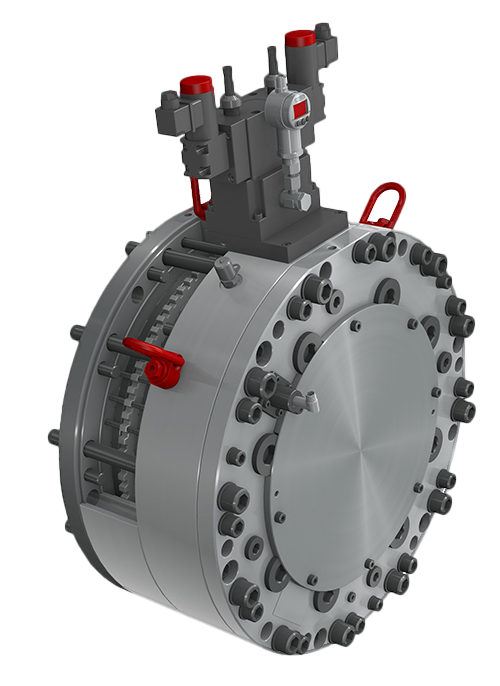

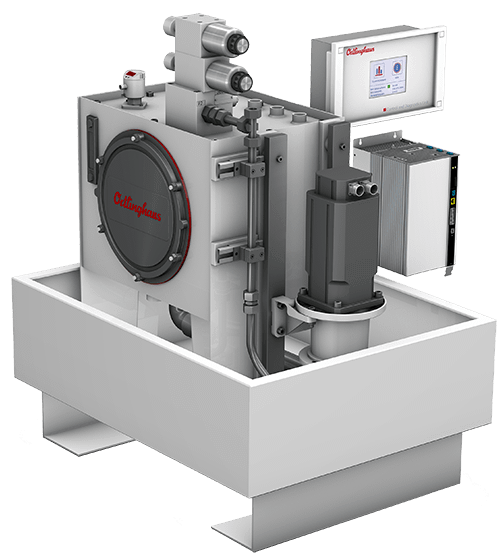

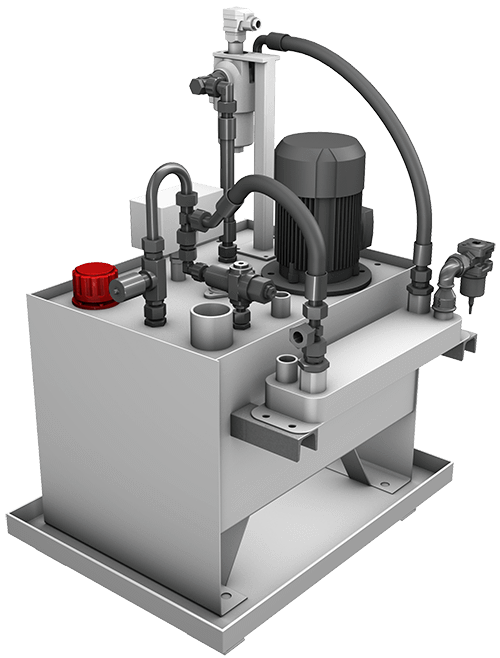

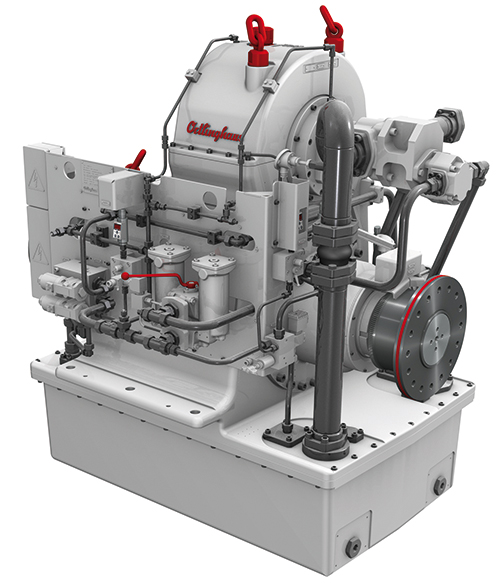

Aus Sicht der Anlagenbetreiber birgt die Ölversorgung der Kupplungen und Bremsen mit Mineralöl ein Gefahrenpotenzial und es gilt auszuschließen, dass dieses Schmier- und Kühlöl – bei ggf. undichten Leitungen – in Verbindung mit glühenden Werkstoffen in Brand geraten könnte. Vor diesem Hintergrund ist Ortlinghaus nun eine bahnbrechende Weiterentwicklung hinsichtlich einsetzbarer schwer entflammbarer Schmierstoffe gelungen. Nach umfangreichen Tests – auch in externen Laboren – konnten unsere Technologie-Experten das Schmiermittel Castrol Anvol SWX 46 freigeben. Neben der Prüfung des Leistungsverhaltens des Reibsystems lag der besondere Fokus auf der Qualifizierung und Modifikation der bestehenden Ansteuerelemente für die sicherheitskonforme Betätigung der Kupplungen und Bremsen. Abb. 2: Ortlinghaus hydraulische Pro-gressivsteuerung - auf die Verwendbarkeit mit Castrol Anvol SWX 46 getestet |

Castrol Anvol SWX 46 ist eine auf synthetischen Polyolestern basierende schwer entflammbare Hydraulikflüssigkeit der Gruppe HFD-U nach DIN 51502 und erfüllt die Anforderungen der 'Factory Mutual Category 1'. Somit steht die Verwendung dieses Schmierstoffes für einen sicheren Arbeitsplatz, verbesserte Systemverfügbarkeit und kann eine günstigere Einstufung der Brandschutzversicherung nach sich ziehen. Bei der Ausrüstung neuer Anlagen können wir die Einflüsse von Castrol Anvol SWX 46 auf unsere Komponenten berücksichtigen und lassen dieses Fachwissen bei den technischen Auslegungen unserer Kupplungen, Bremsen und Steuerungen einfließen. Bei bestehenden Anlagen ist ein Wechsel des Schmierstoffes auf Castrol Anvol SWX 46 nur nach einer schriftlichen Freigabe durch Ortlinghaus zulässig. |

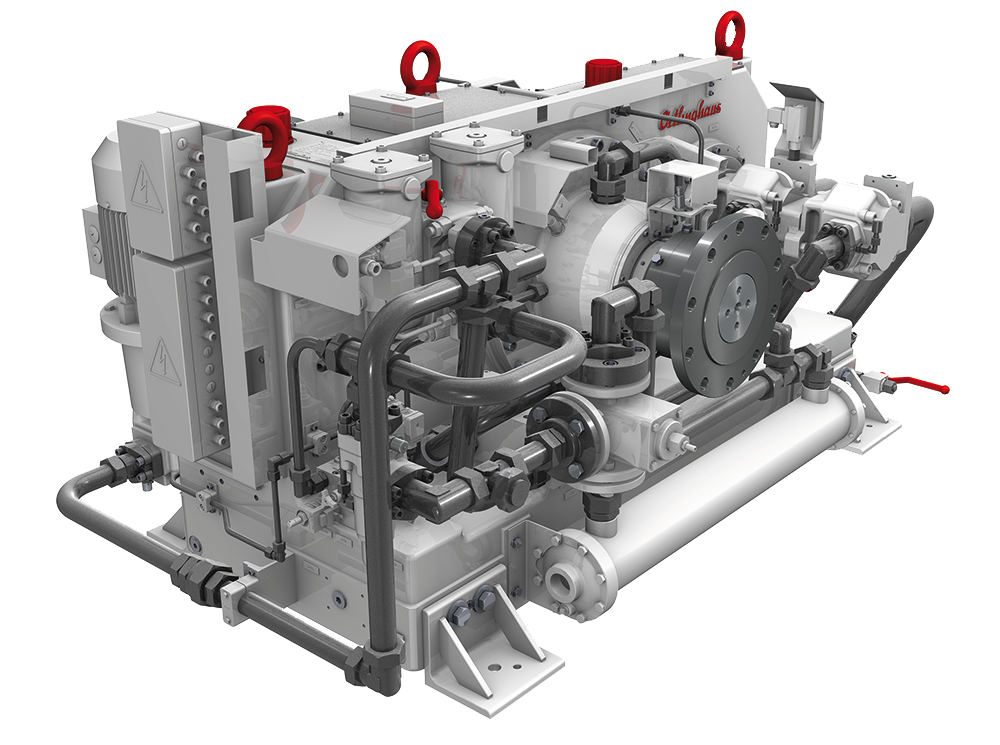

Sicherheitsbremsen in Ortlinghaus Qualität

Sicherheitsbremsen in Ortlinghaus Qualität