Plates. Ortlinghaus Quality.

Plates for dry- and wet-running clutches and brakes by industries.

- Torque:

- 150 - 1,600,00 Nm

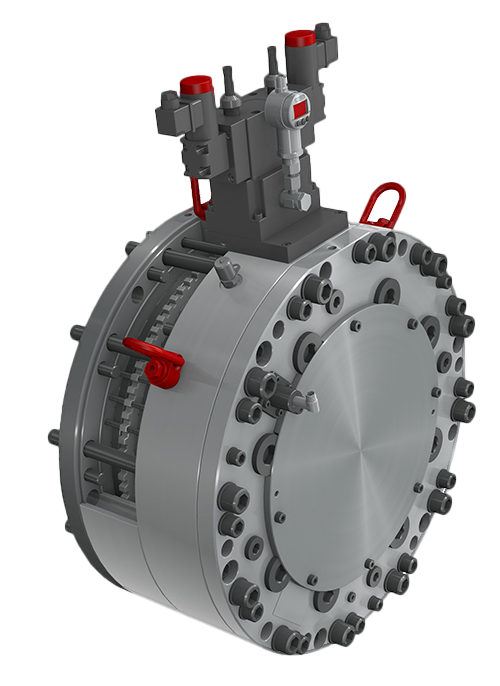

Plates Dimension- and Torque range in Press technology.

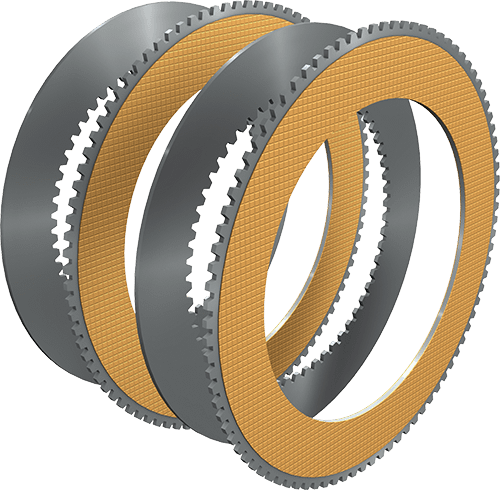

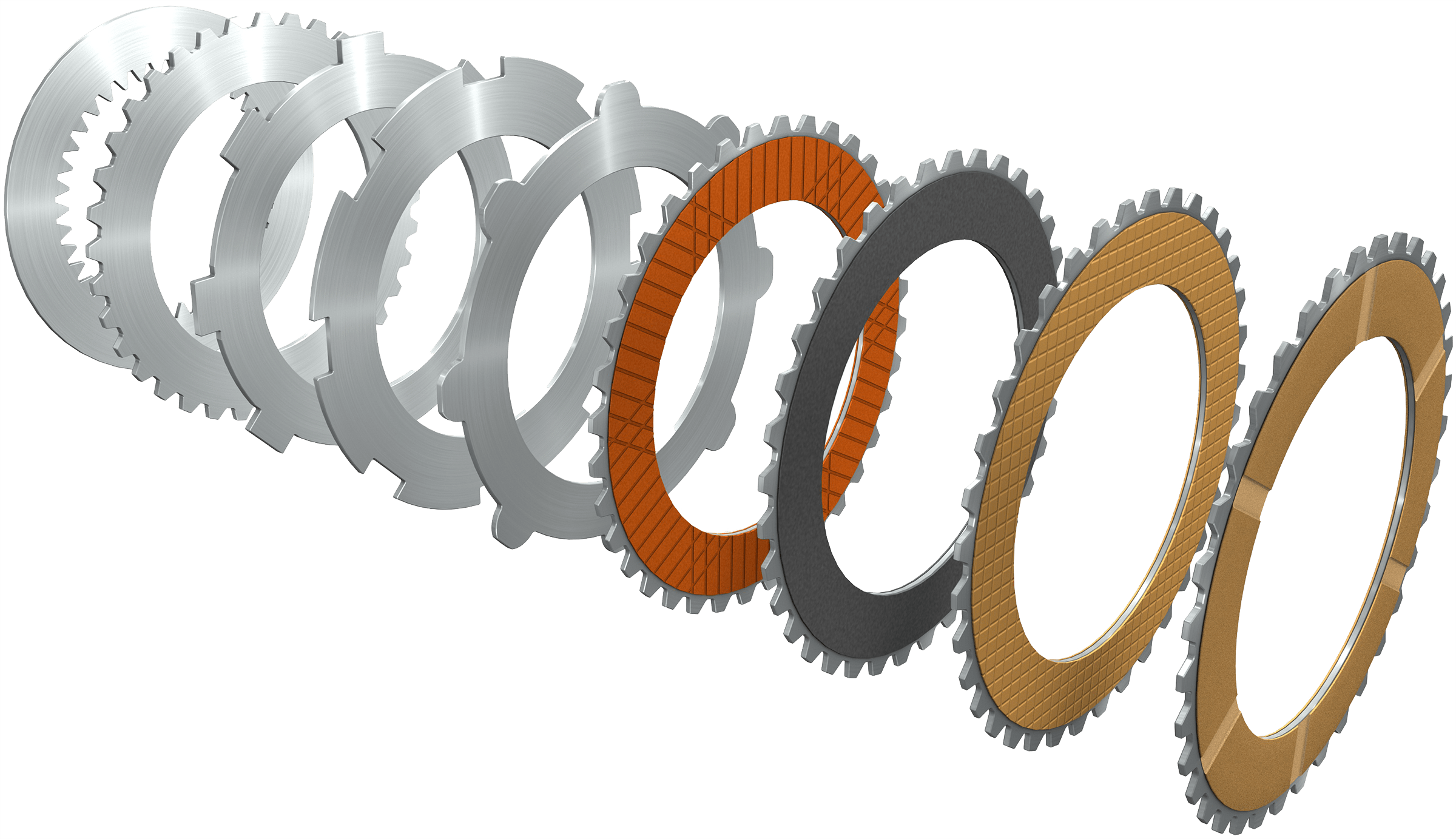

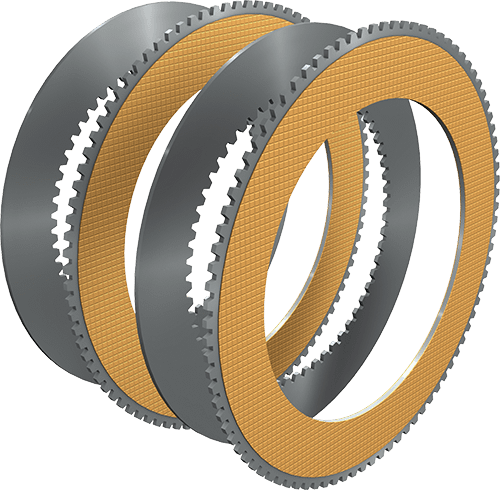

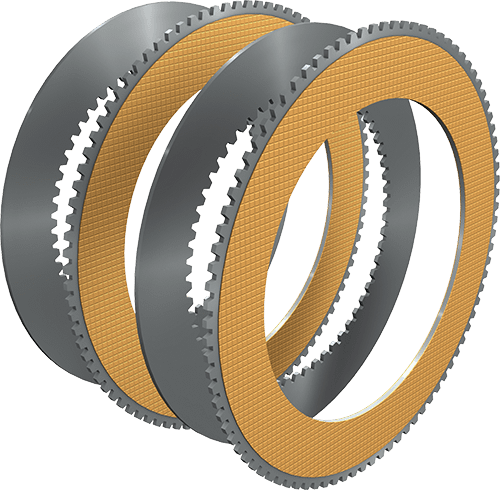

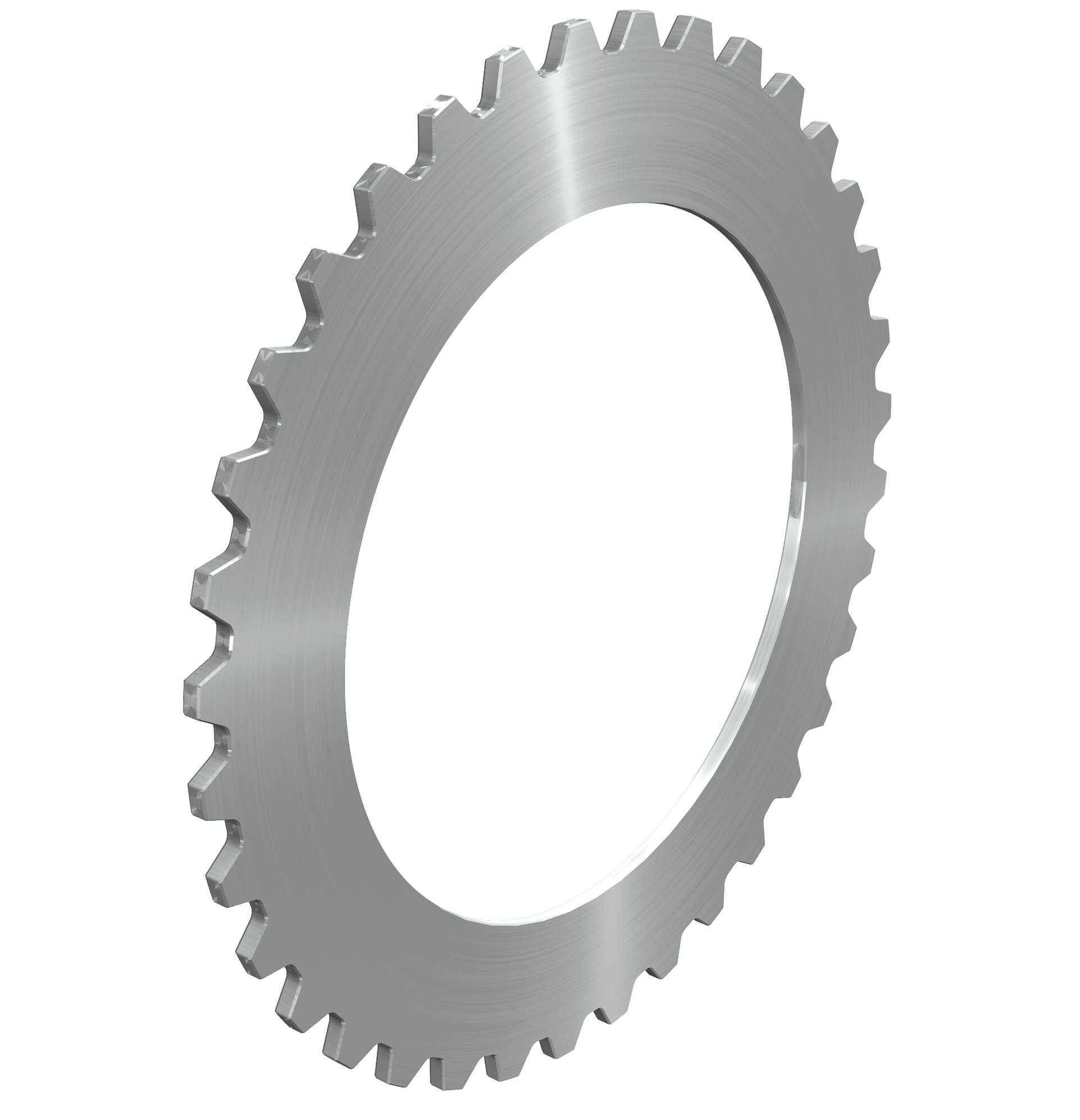

For dry- and wet-running clutches and brakes, Ortlinghaus is able to provide a very comprehensive range of plates. The plates and the friction surface are important functional elements in every clutch and brake, and have been developed in many different ways since the early days of clutches and brakes. The choice of friction system depends on the application: in general, one plate with friction material works together with a counterplate of steel or cast iron. The inner and outer plates are mounted with the other drive components by lugs and slots, and the spline is in accordance with DIN 867 and DIN 5480 as well as other standards. In addition, holes in the plate for studs and special shapes in accordance with customer requirements are available.

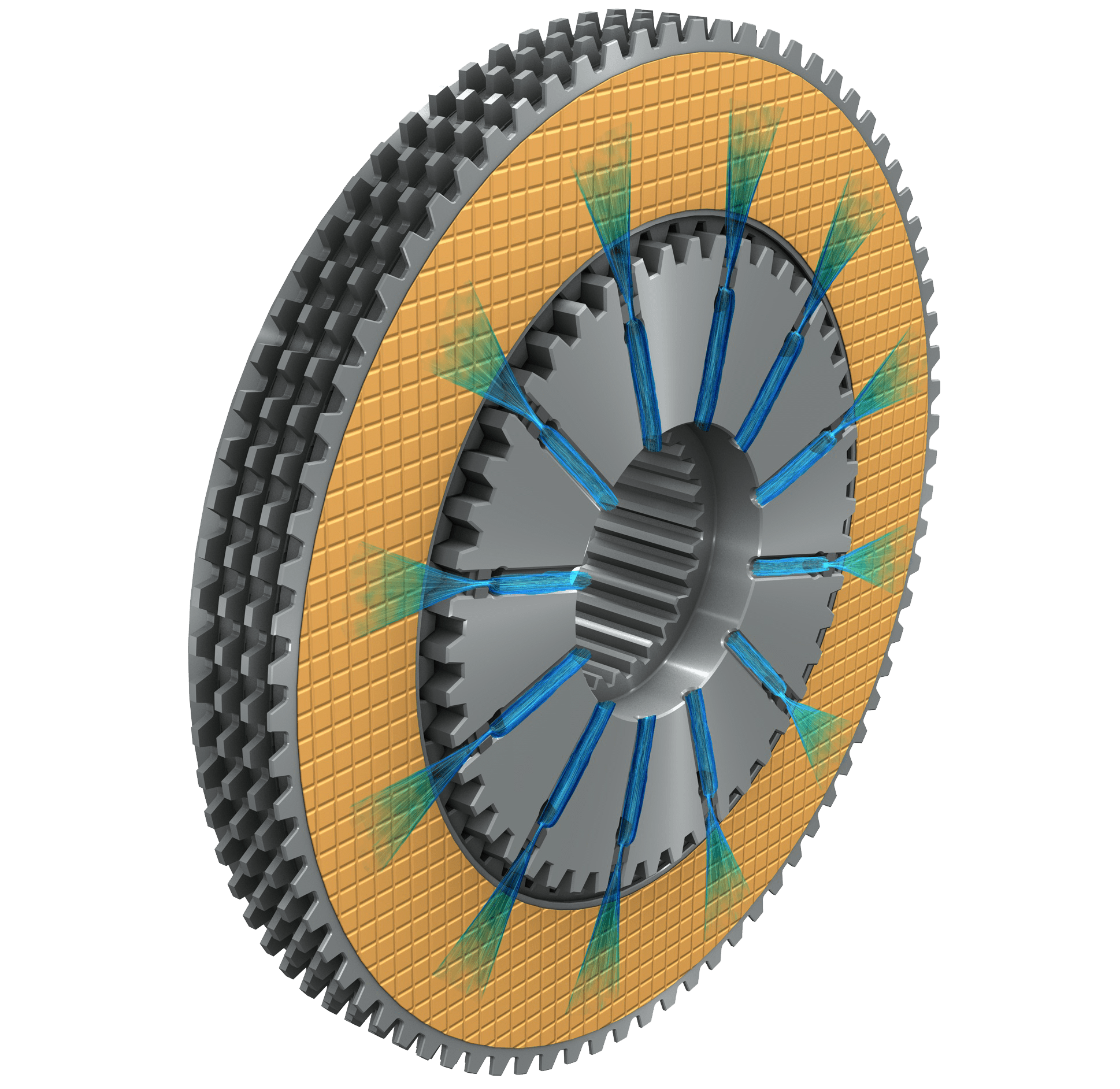

Combined with a multi-plate clutch or brake, these plates come in a multitude of different dimensions, friction combinations, and surface patterns.

- Torque:

- 150 - 1,600,00 Nm

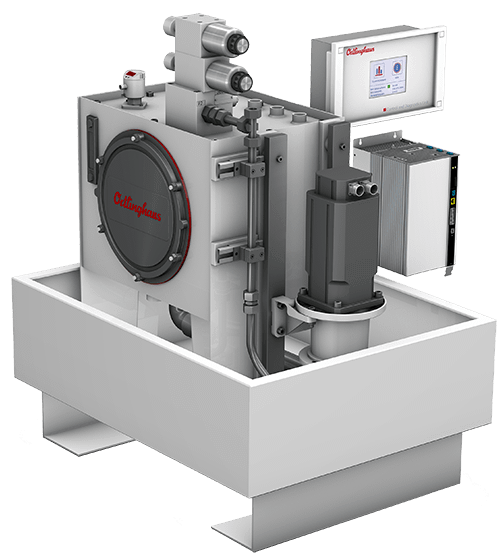

Plates Dimension- and Torque range in Marine technology.

For dry- and wet-running clutches and brakes, Ortlinghaus is able to provide a very comprehensive range of plates. The plates and the friction surface are important functional elements in every clutch and brake, and have been developed in many different ways since the early days of clutches and brakes. The choice of friction system depends on the application: in general, one plate with friction material works together with a counterplate of steel or cast iron. The inner and outer plates are mounted with the other drive components by lugs and slots, and the spline is in accordance with DIN 867 and DIN 5480 as well as other standards. In addition, holes in the plate for studs and special shapes in accordance with customer requirements are available.

For dry- and wet-running clutches and brakes, Ortlinghaus is able to provide a very comprehensive range of plates. The plates and the friction surface are important functional elements in every clutch and brake, and have been developed in many different ways since the early days of clutches and brakes. The choice of friction system depends on the application: in general, one plate with friction material works together with a counterplate of steel or cast iron. The inner and outer plates are mounted with the other drive components by lugs and slots, and the spline is in accordance with DIN 867 and DIN 5480 as well as other standards. In addition, holes in the plate for studs and special shapes in accordance with customer requirements are available.

Combined with a multi-plate clutch or brake, these plates come in a multitude of different dimensions, friction combinations, and surface patterns.

- Torque:

- 50 - 1,600,00 Nm

- Rotations per minute:

- Up to 5,000 min

- Friction Diameter:

- 60 - 460 mm

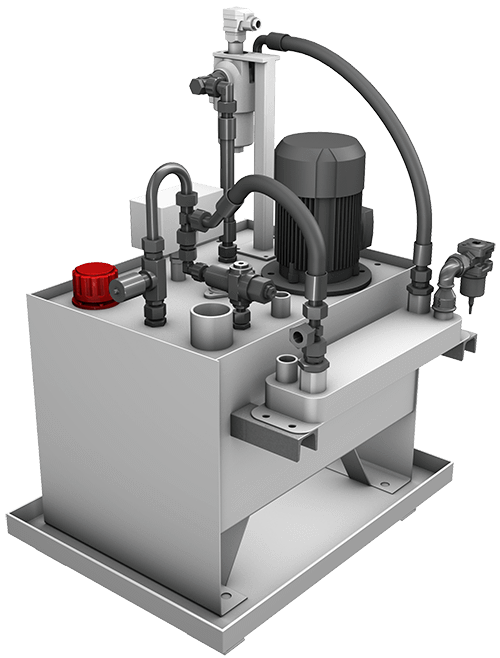

Plates Dimension- and Torque range in Construction technology.

For dry- and wet-running clutches and brakes, Ortlinghaus is able to provide a very comprehensive range of plates. The plates and the friction surface are important functional elements in every clutch and brake, and have been developed in many different ways since the early days of clutches and brakes. The choice of friction system depends on the application: in general, one plate with friction material works together with a counterplate of steel or cast iron. The inner and outer plates are mounted with the other drive components by lugs and slots, and the spline is in accordance with DIN 867 and DIN 5480 as well as other standards. In addition, holes in the plate for studs and special shapes in accordance with customer requirements are available.

Combined with a multi-plate clutch or brake, these plates come in a multitude of different dimensions, friction combinations, and surface patterns.

- Torque:

- 200 - 12,000 Nm

- Friction Diameter:

- 90 - 280 mm

Plates Dimension- and Torque range in Agriculture technology.

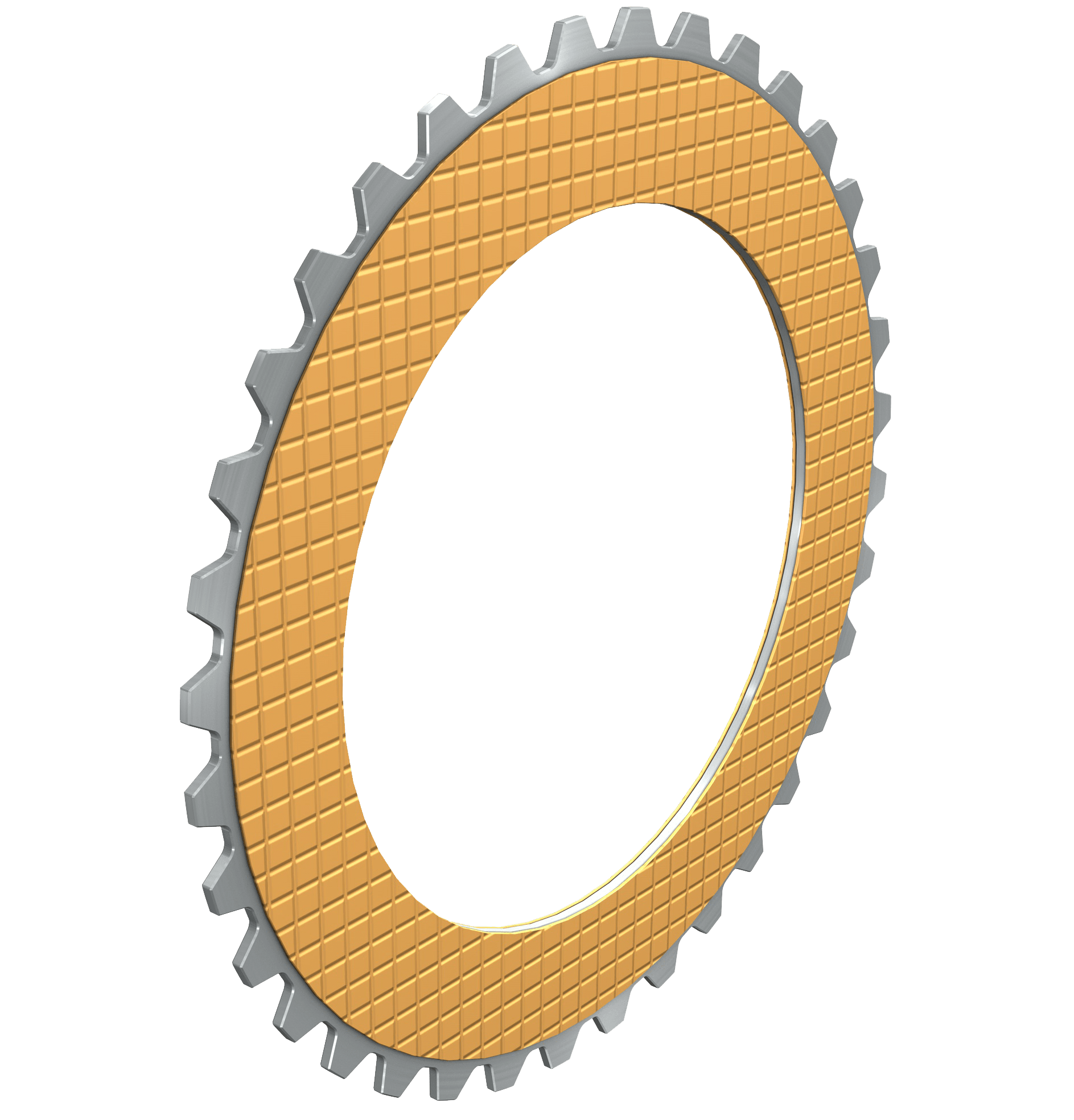

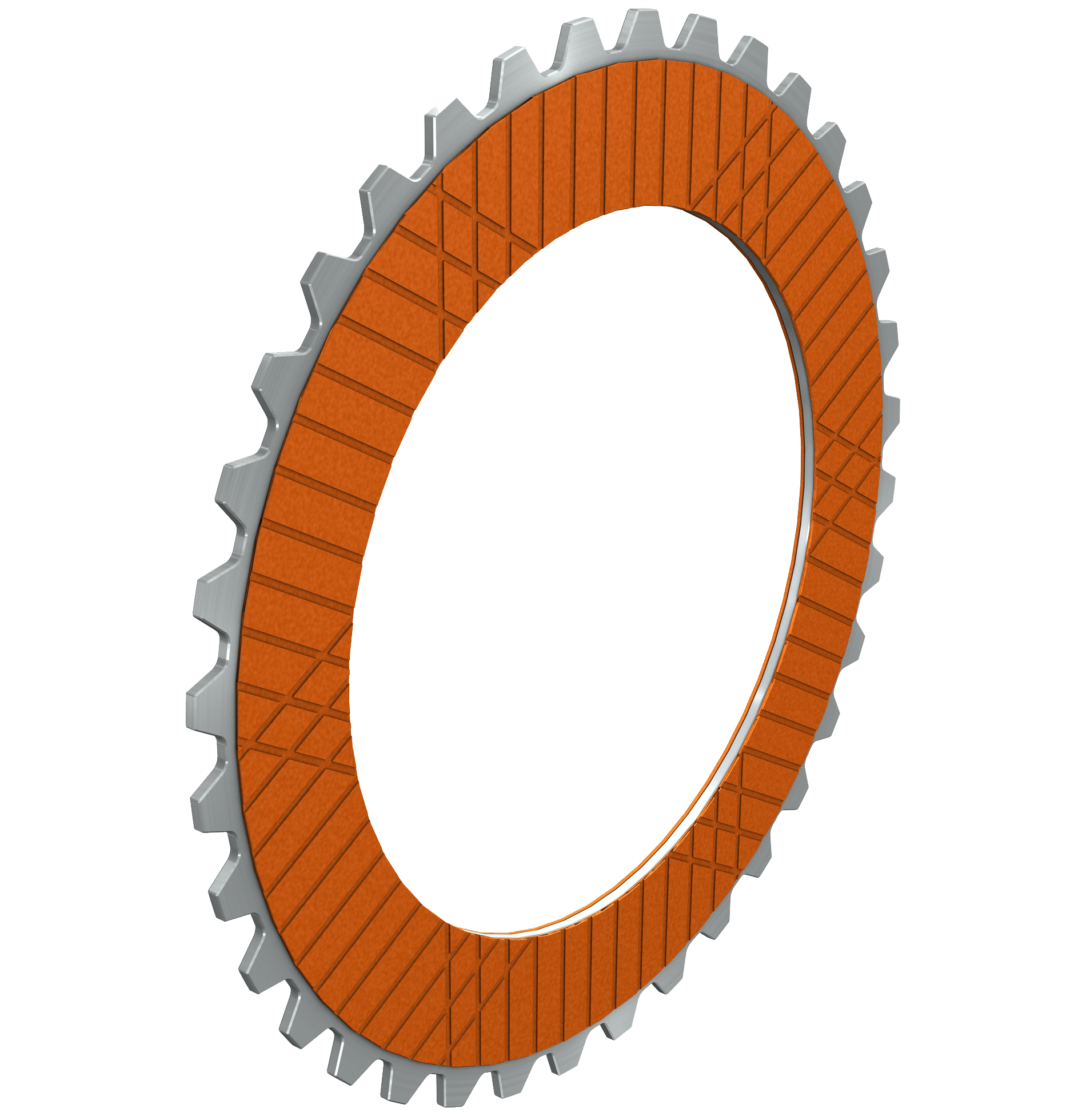

In the case of a wet-running application however, the grooving of the friction surface is critical for directing the cooling oil accurately. Many different surface patterns are available, especially in the case of sintered plates, for a variety of applications. These include, for example, spiral grooves, radial grooves or a combination of the two, honeycomb and sunburst patterns, and various other different forms of oil channels. Paper linings are also used.

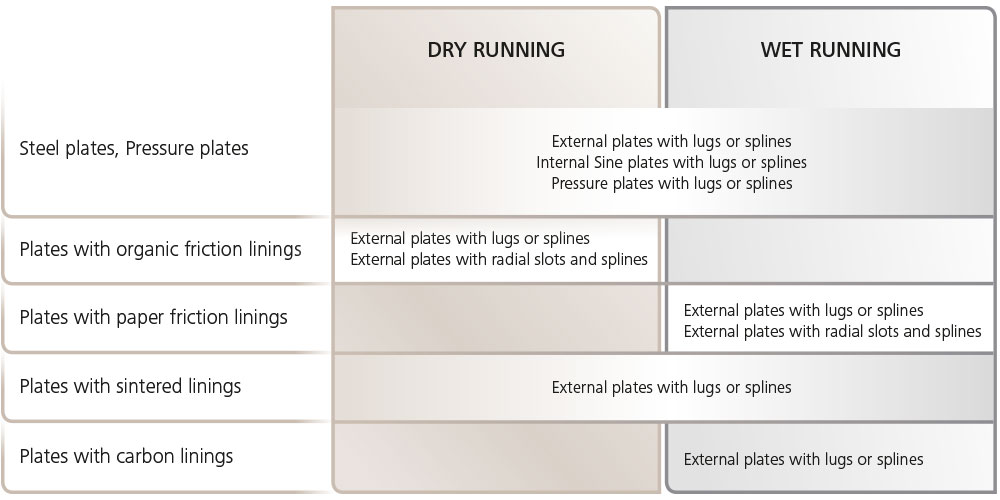

In the case of a dry-running application, it is primarily the level of wear, coefficient of friction, and noise that are influenced by the surface. Normally, a pair of plates consisting of "organic" friction lining on one plate and a counterplate of steel or special cast iron on the other are used. Sintered, metallic friction linings are also used for particular applications.

In the case of a wet-running application however, the grooving of the friction surface is critical for directing the cooling oil accurately. Many different surface patterns are available, especially in the case of sintered plates, for a variety of applications. These include, for example, spiral grooves, radial grooves or a combination of the two, honeycomb and sunburst patterns, and various other different forms of oil channels. Paper linings are also used.

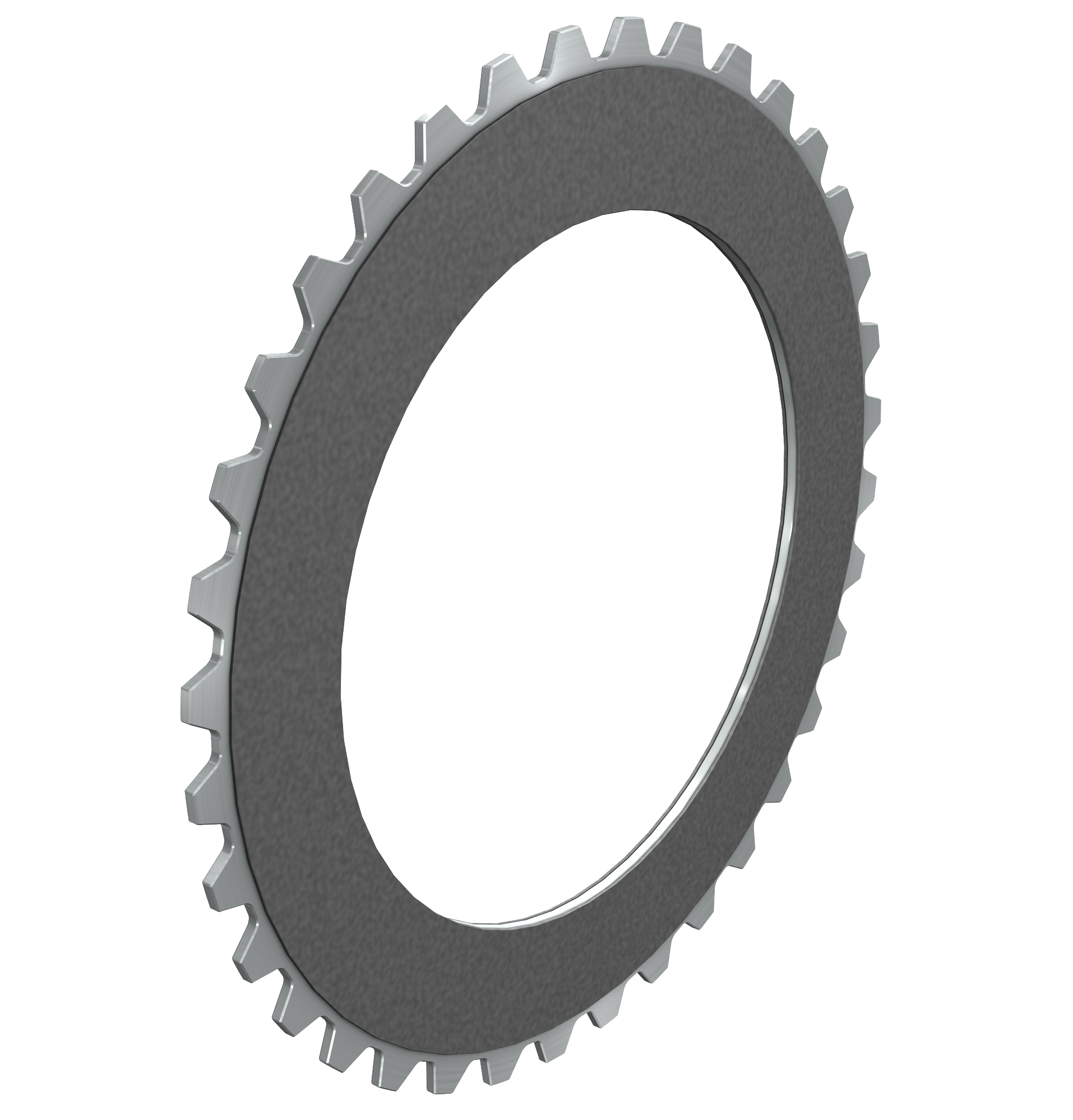

Dry-running plates | Dry-running platesGenerally dry-running clutches and brakes use a pair of plates consisting of "organic" friction lining on one plate and a counterplate of steel or special cast iron. Although this friction combination is subject to wear, it has become a standard due to its hard wearing capabilities. Sintered, metallic friction linings are also used for particular applications. The friction linings described here are riveted or bonded to the plates in the form of rings or segments or are applied by a sintering process. |

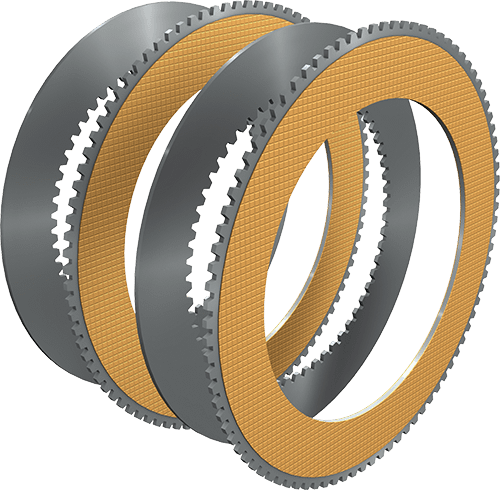

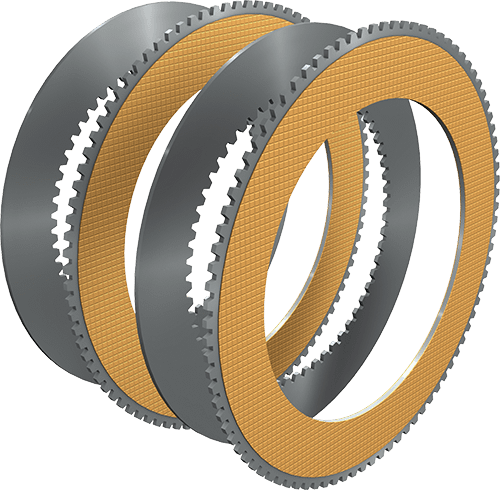

Wet-running plates | Wet-running platesWhen considering "wet-running" plates, it is necessary to consider the lubricating and cooling oil, since this plays a decisive roll in the frictional process. In wet-running clutches and brakes the "classical" friction combination of steel/steel is today being replaced more and more by steel/sintered coating. The standard qualities of sintered coating are able to cover a wide range of conditions which are placed on high performance friction linings. In addition, the sinter is capable of being varied in terms of composition porosity and compatibility with oil enabling it to fulfill a wide range of special tasks. Of special interest within the range of wet- running plates is the friction combination steel/paper lining. This is being used to an ever greater extent in transmission systems in general mechanical engineering and in the motor vehicle industry. This is due to its extraordinary frictional behaviour and its almost total freedom from wear. |

Wet-running sinter-lining plates | Wet-running sinter-lining plates

|

Dry-running sinter-lining plates | Dry-running sinter-lining plates

|

Wet-running paper plates | Wet-running paper plates

|

Dry-running organic-lining plates | Dry-running organic-lining plates

|

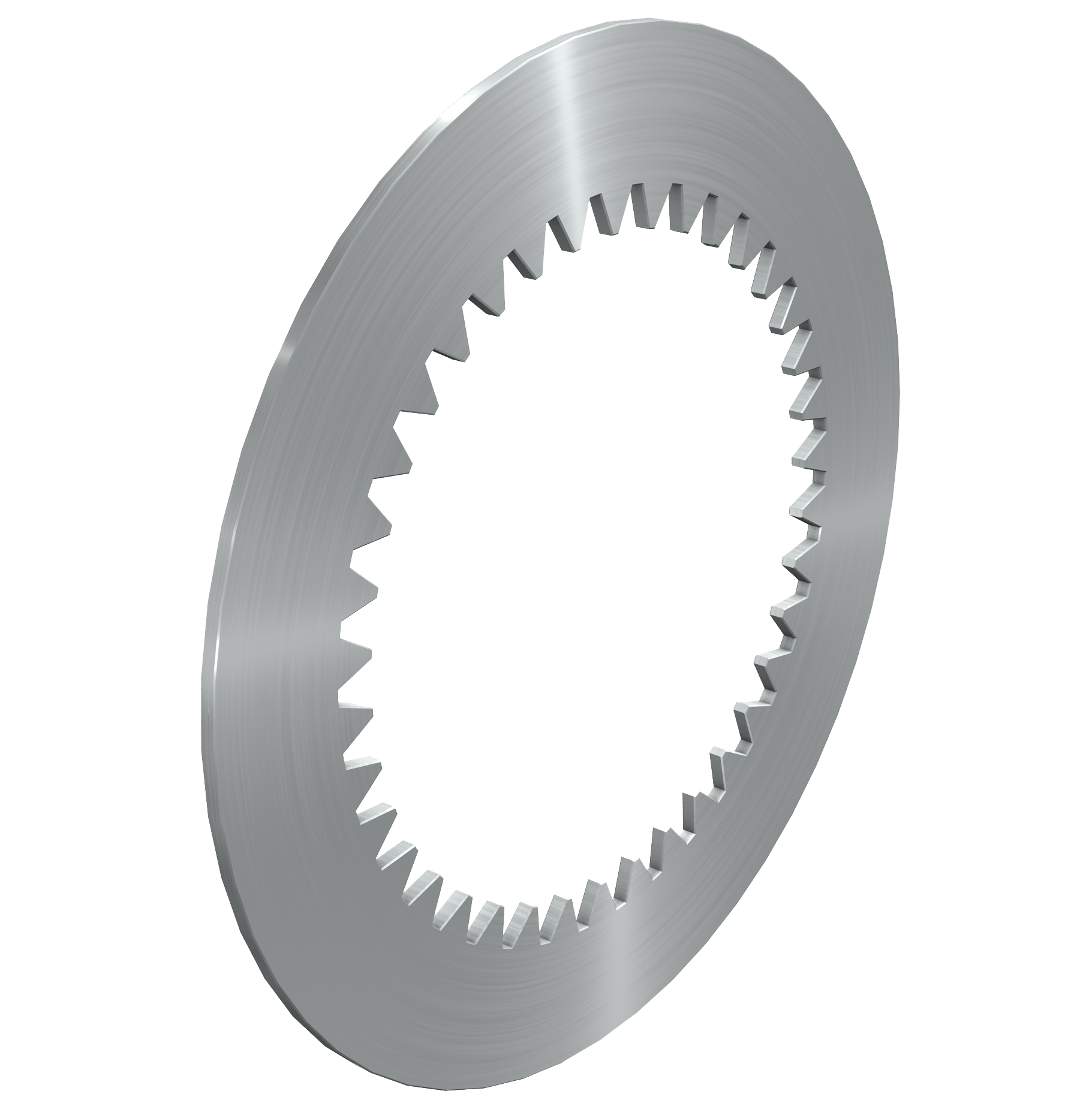

Steel plates | Steel plates

|

Plates with splines | Plates with splines

|

Plates with lugs | Plates with lugs

|

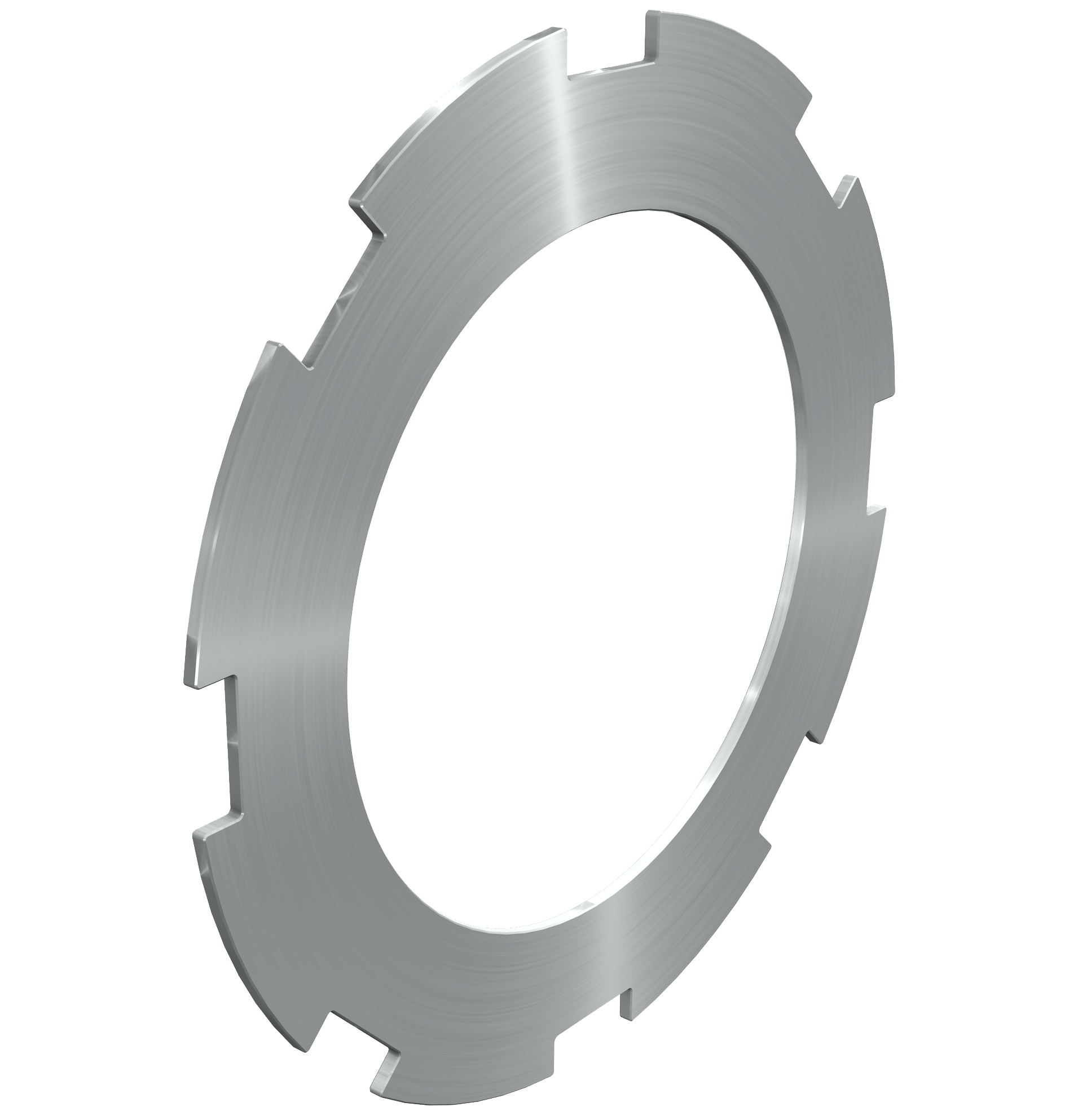

Plates with radial slots | Plates with radial slots

|

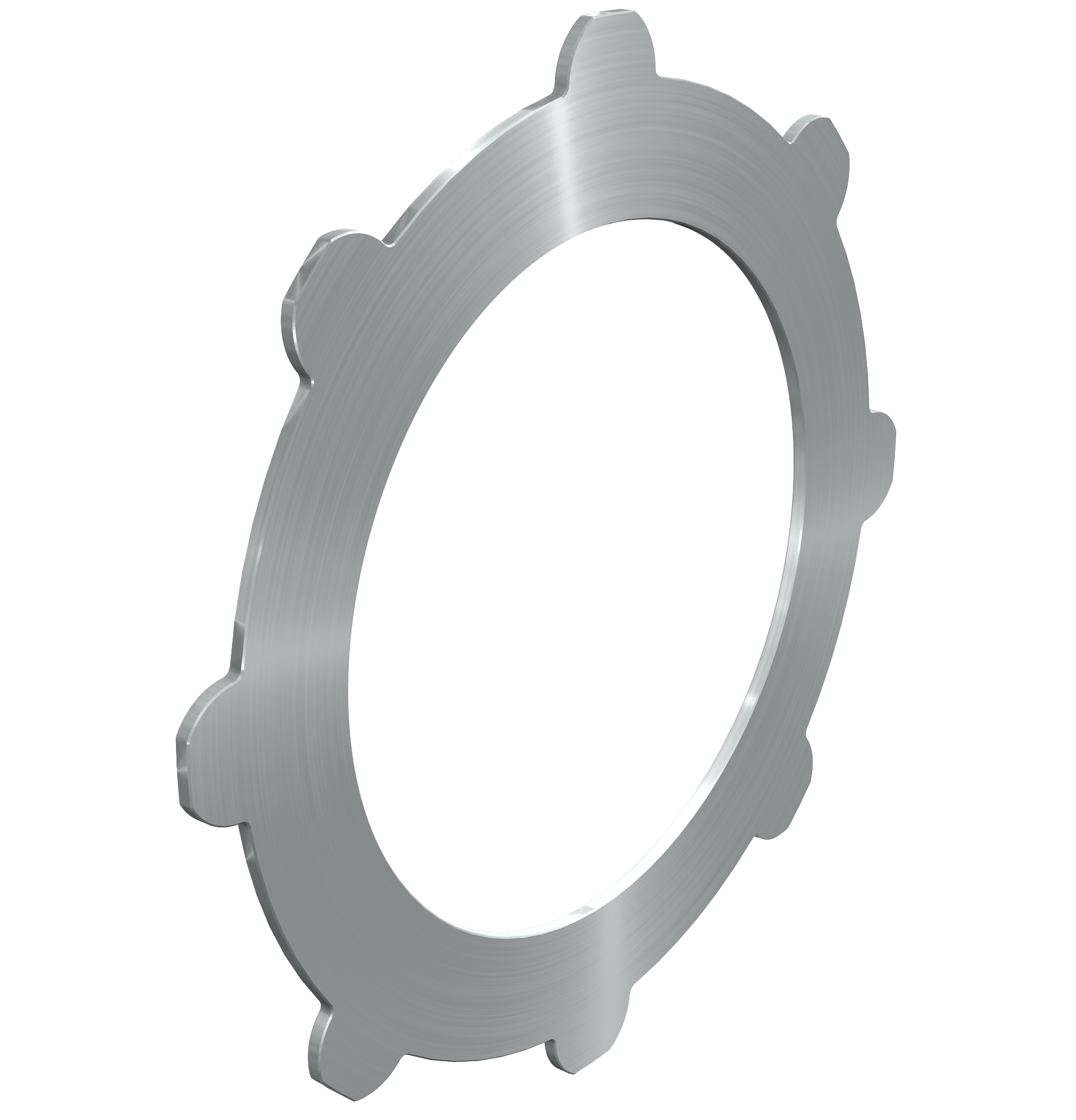

Plates with rounded lugs | Plates with rounded lugs

|