|

Ortlinghaus wet-running clutches and brakes in hot forging and rolling mills |

Further development on the usability of flame-retardant lubricants |

|

|

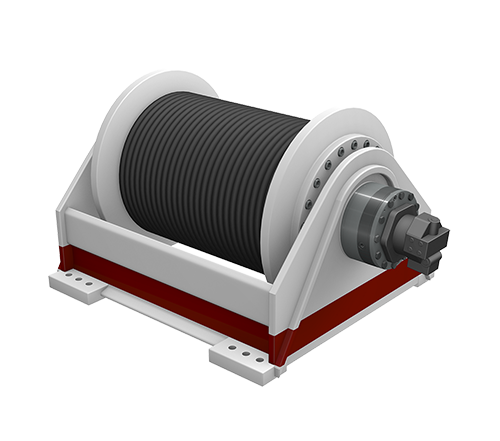

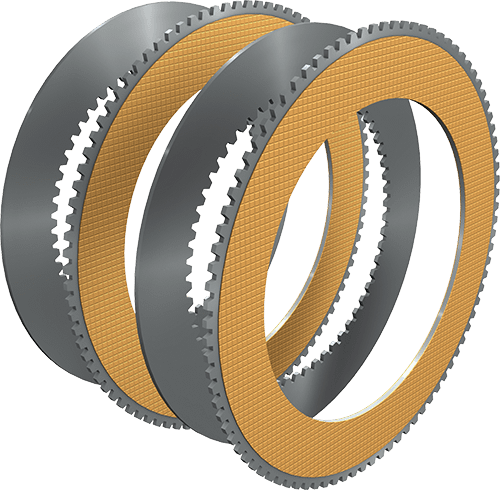

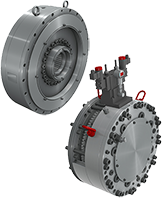

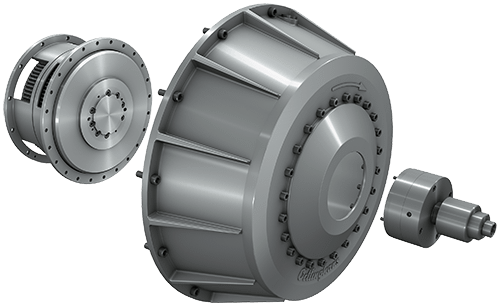

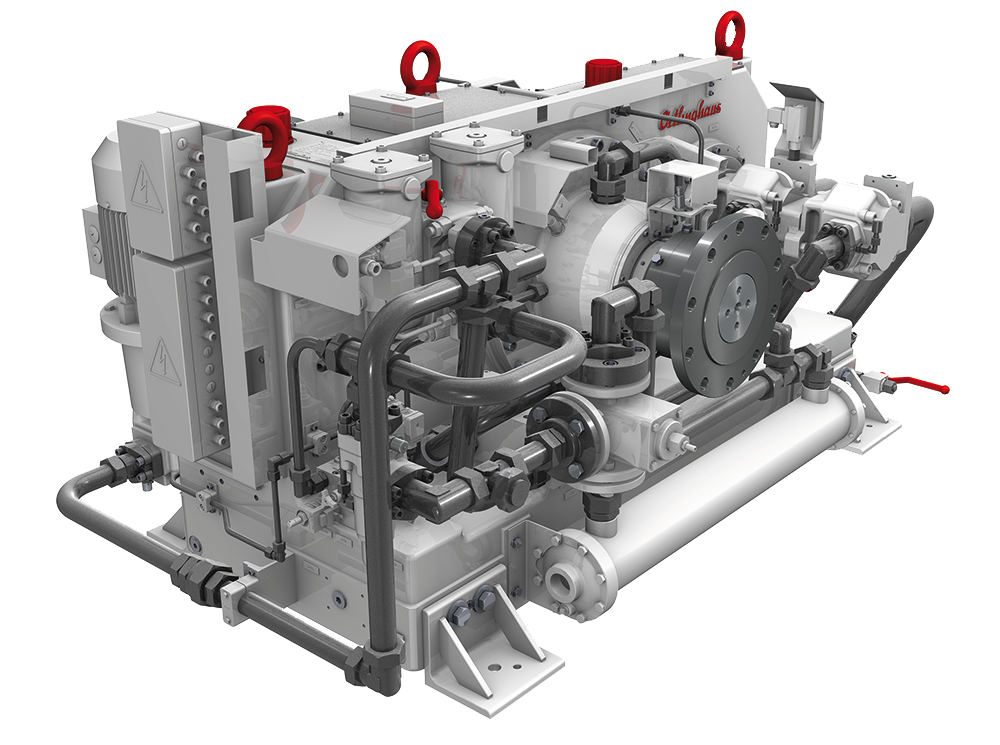

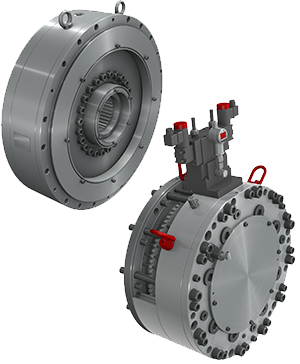

For decades, Ortlinghaus wet-running clutches, brakes and clutch-brake combined units have performed reliably in hot forging and rolling mills. In these clutches and brakes, the contact surfaces of the friction elements are permanently supplied with lubricating and cooling oil. The sintered plates used in such wet-running systems use a friction material containing bronze, which stores the oil molecules from the constant oil flow in their surfaces. Figure 1: Wet-running plate pack with Original Ortlinghaus Sinter Plates As a result, when the clutch is activated, there is virtually no abrasion in the friction linings, which results in largely wear-free clutch and brake systems. |

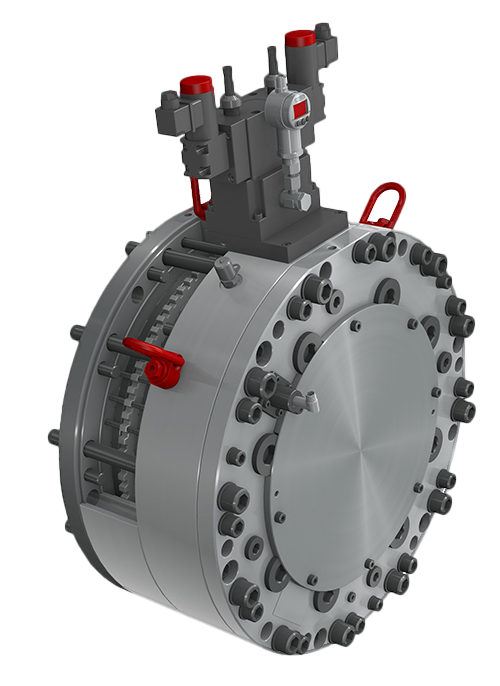

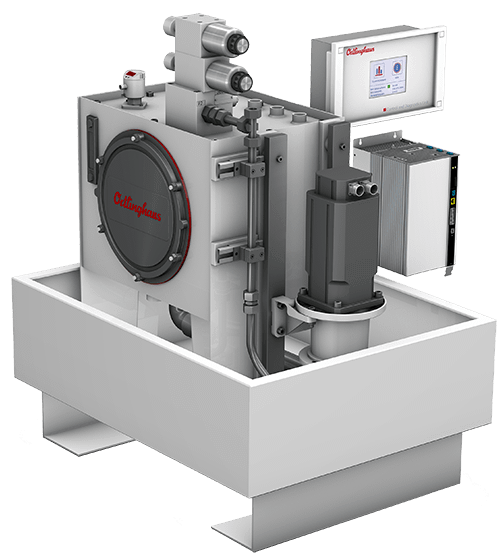

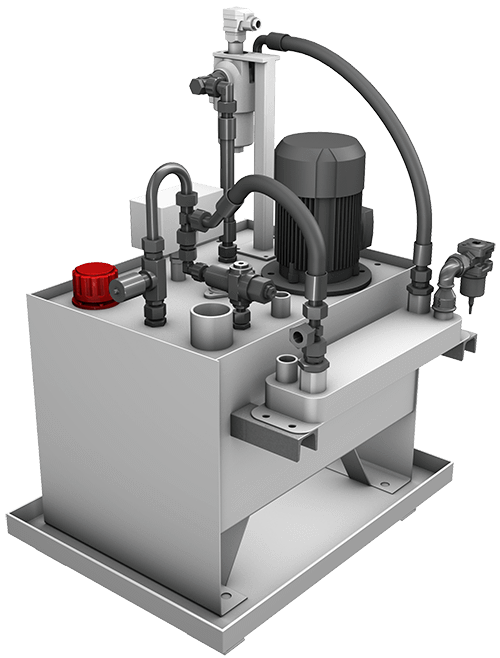

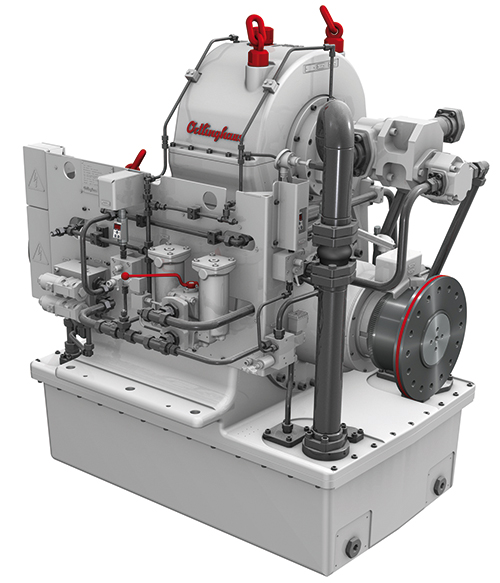

From the point of view of the hot forging and rolling mill companies, the oil supply with mineral oil to the clutches and brakes poses a potential hazard and it must be ruled out that this lubricating and cooling oil could catch fire in connection with glowing materials in the eventuality of a leaky pipe. Against this background, Ortlinghaus has now achieved a groundbreaking evolution with regard to usable flame-retardant lubricants. After extensive tests – in both Ortlinghaus and external laboratories – our technology experts were able to approve the use of lubricant Castrol Anvol SWX 46. In addition to testing the performance of the friction system, special attention was on the qualification and modification of the existing control elements for safety-compliant actuation of the clutches and brakes. Figure 2: Ortlinghaus hydraulic Progressive Control – tested for usability with Castrol Anvol SWX 46 |

Castrol Anvol SWX 46 is a synthetic polyol ester-based, flame-retardant hydraulic fluid of the HFD-U group according to DIN 51502 and meets the requirements of 'Factory Mutual Category 1'. Thus, the use of this lubricant stands for a safe workplace, improved system availability and can result in a more favorable classification for fire protection insurance. When equipping new hot forging and rolling mill presses, we can take into account the influences of Castrol Anvol SWX 46 on our components and incorporate this expertise into the technical calculation of our clutches, brakes and controls. In existing systems, changing the lubricant to Castrol Anvol SWX 46 is only permitted after written approval by Ortlinghaus. |