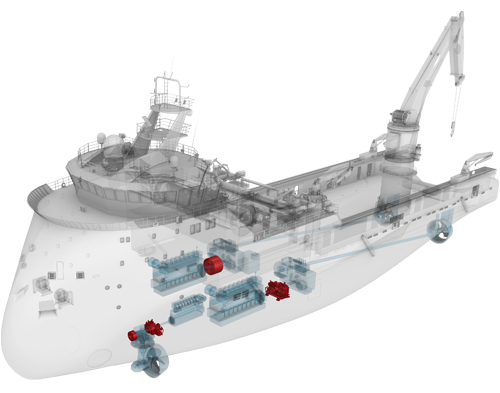

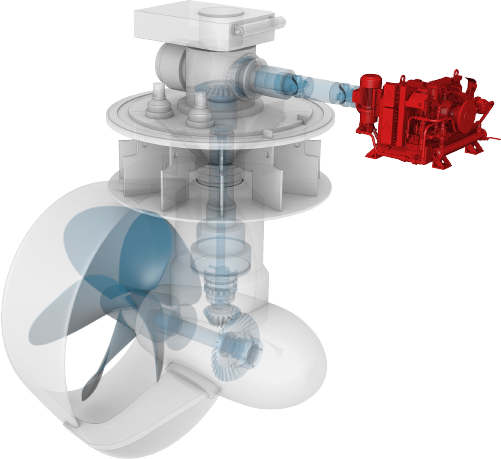

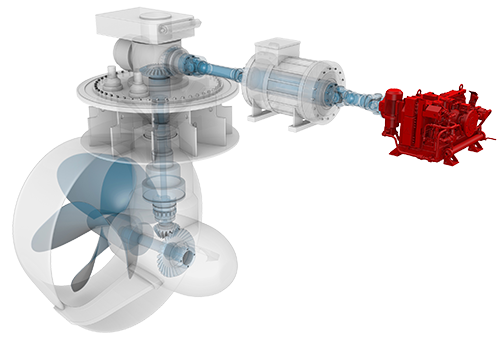

Z-drive in Propulsion technology.

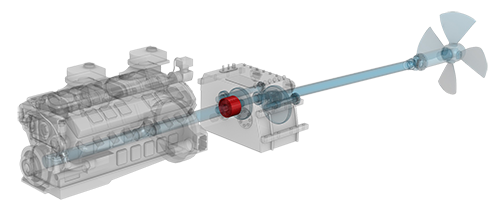

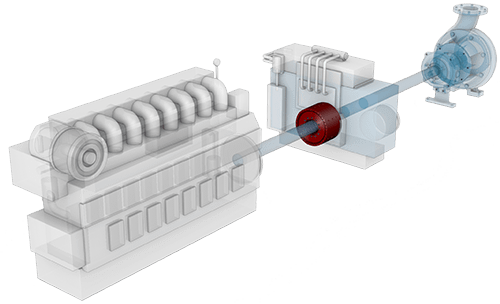

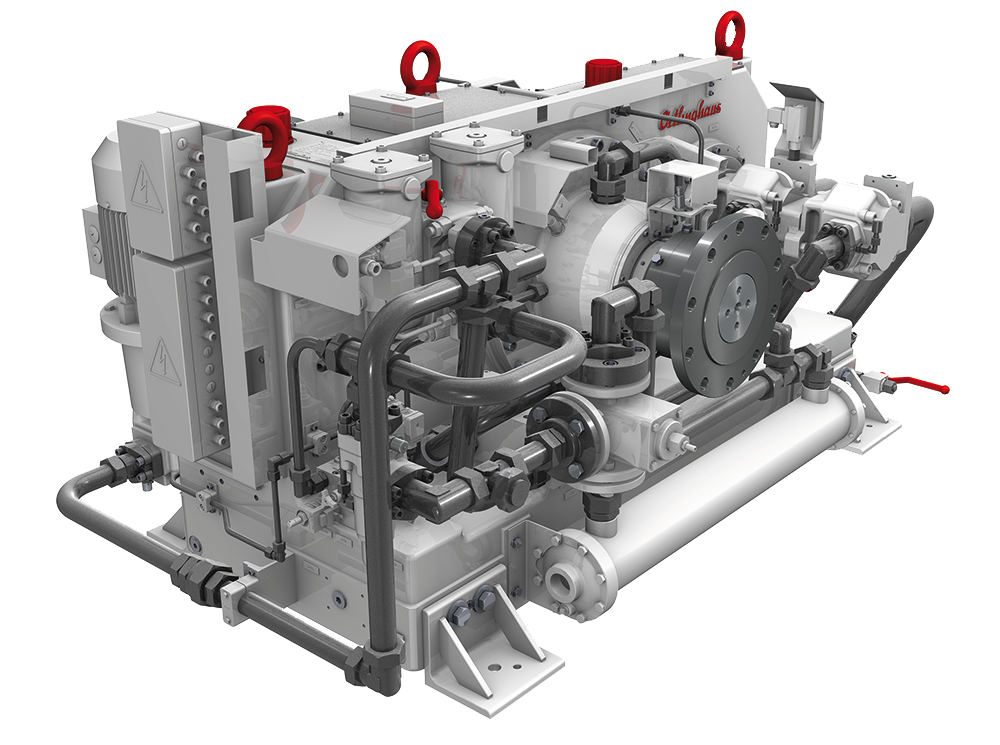

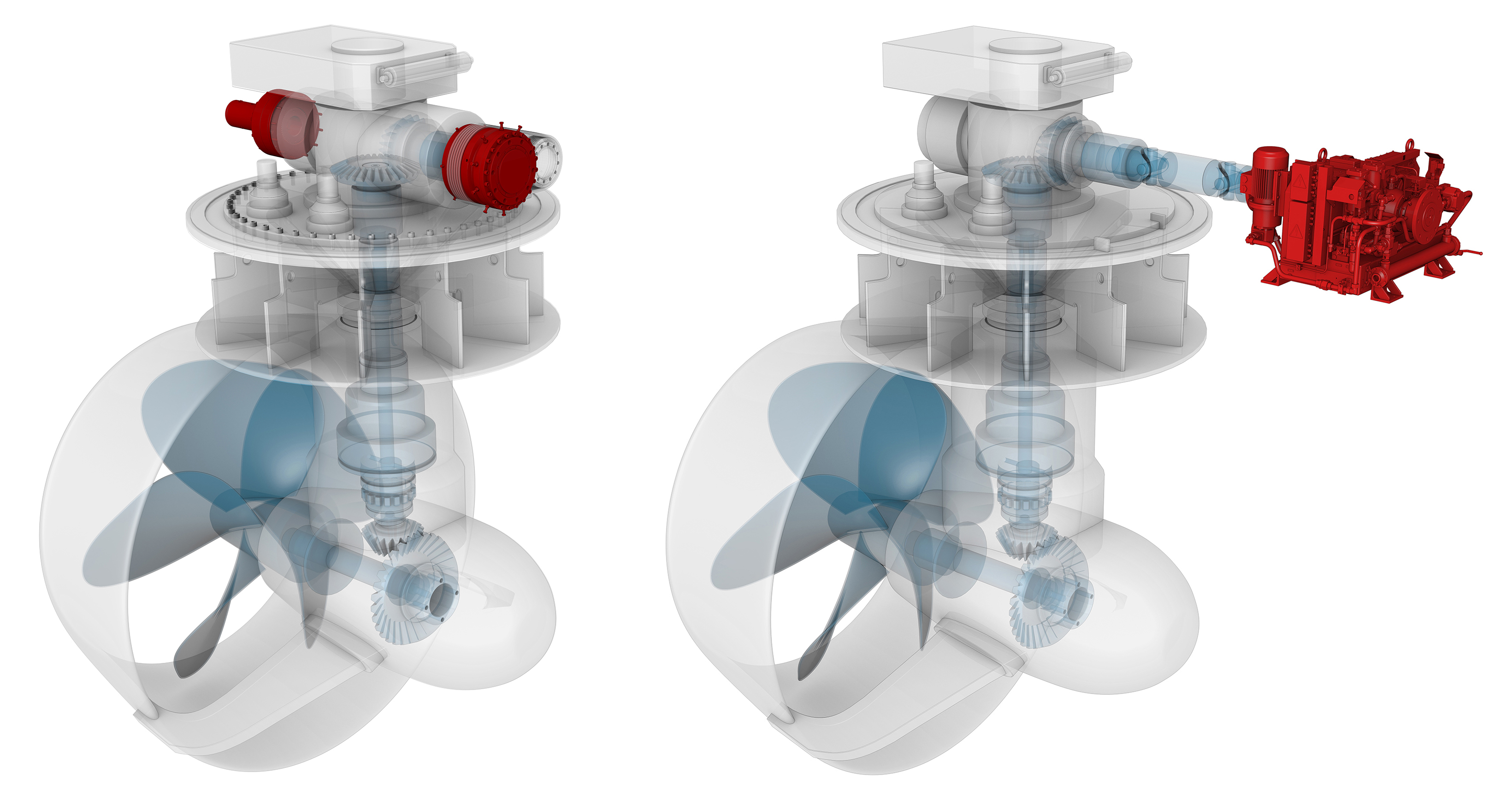

Prop.act | Prop.actProp.act – our new shifting clutch system is a hydraulically actuated, wet-running clutch unit. It is a stand-alone system, wich is bottom mounted. Within the drive train it can be connected between two shaft ends of the cardan shafts for example. Prop.act impresses with a series of technical innovations and advantages, which make it efficient and economical to use. The Prop.act clutch system can be applied in hybrid propulsions between the E-engine and the diesel engine for example. In this case the power take off can't be used because a stand by pump has to be installed. |

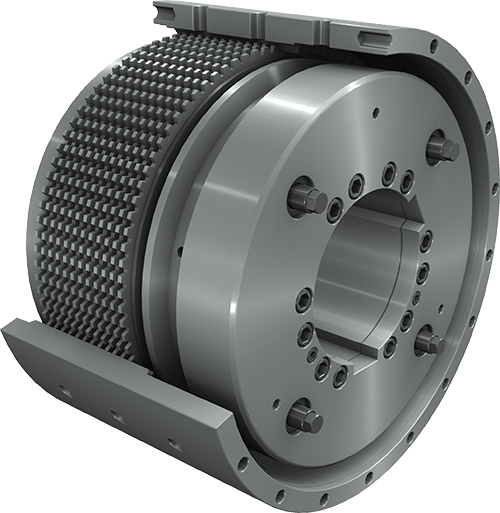

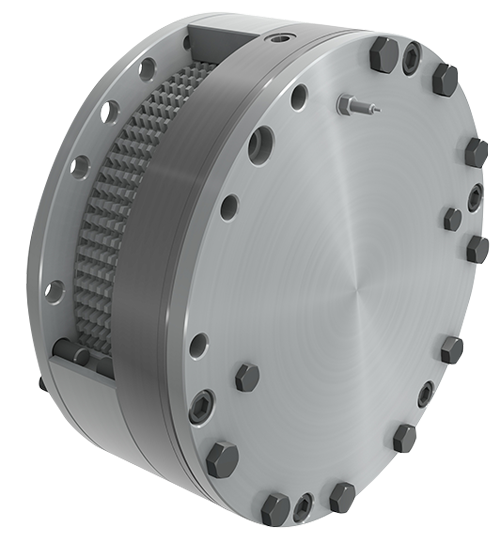

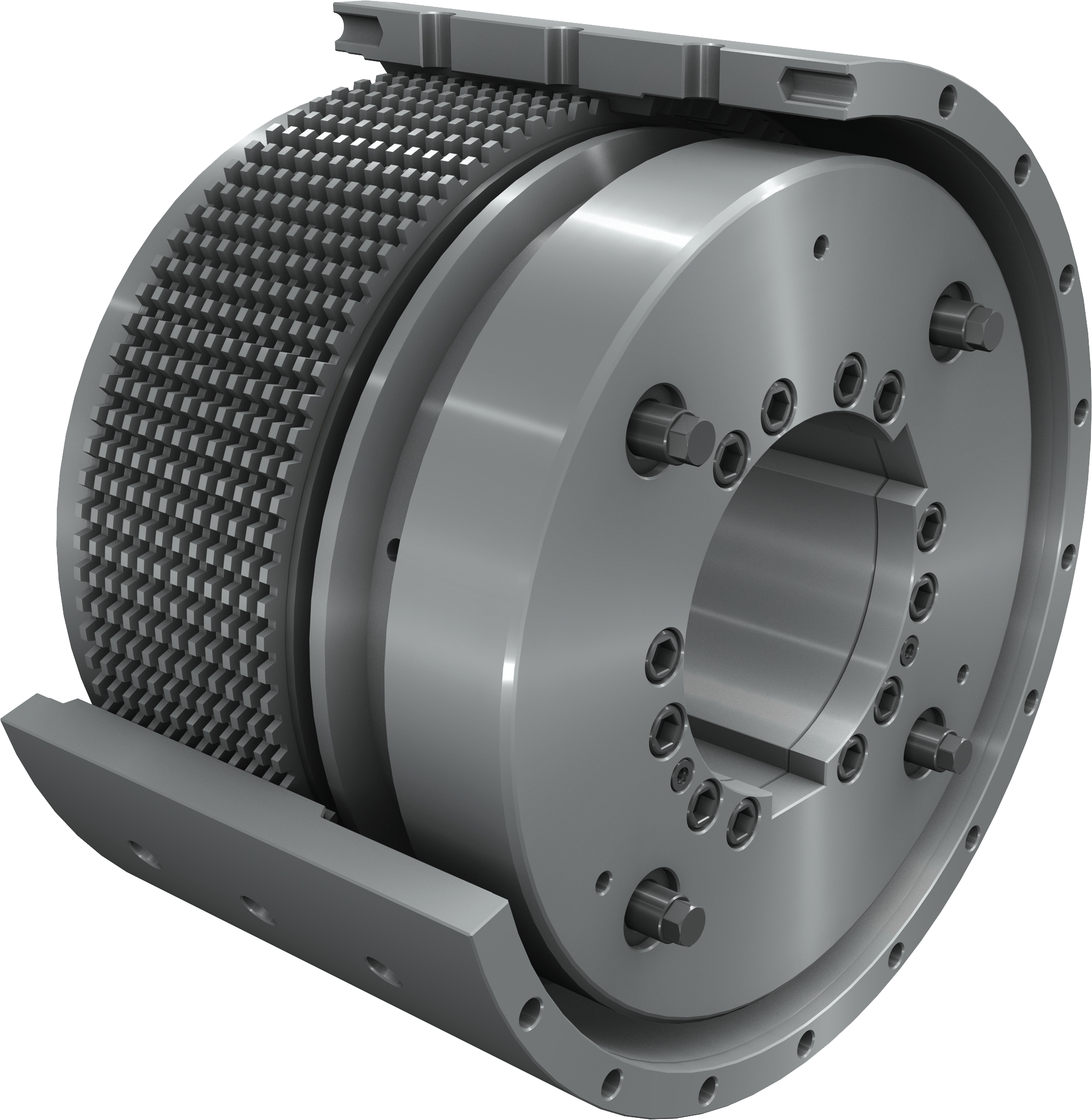

Hydraulical clutch | Series 002/021/202 | Hydraulical clutch | Series 002/021/202Based on our friction linings, which have been tried and trusted for many years in the marine sector, clutches in this series reconcile high torque and thermal absorption rates as well as a favorable outer diameter. A high shaft diameter can also be used. Due to their broad power spectrum, smaller sizes can be achieved with corresponding weight and cost benefits, especially in higher torque ranges. The optimized outer diameter makes shorter distances between axles possible, and in this way offers clear savings potential in the gearbox. The hydraulic multi-plate clutch impresses with its comprehensive service friendliness. The plate pack, which is wear-free under the specified conditions, can be accessed from either side depending on the model, and ensures an easy, safe, and swift replacement of the plate pack. The special design also ensures that other components cannot fall out during replacement. The Ortlinghaus muti-plate clutches safely accelerate even large propellers and generators. This optimal further development of our tried-and-tested technology sets today’s industry standards.

|

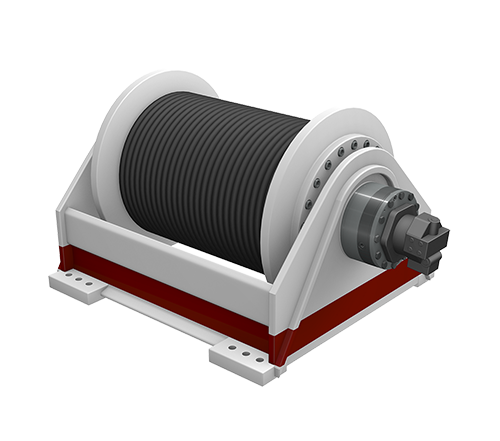

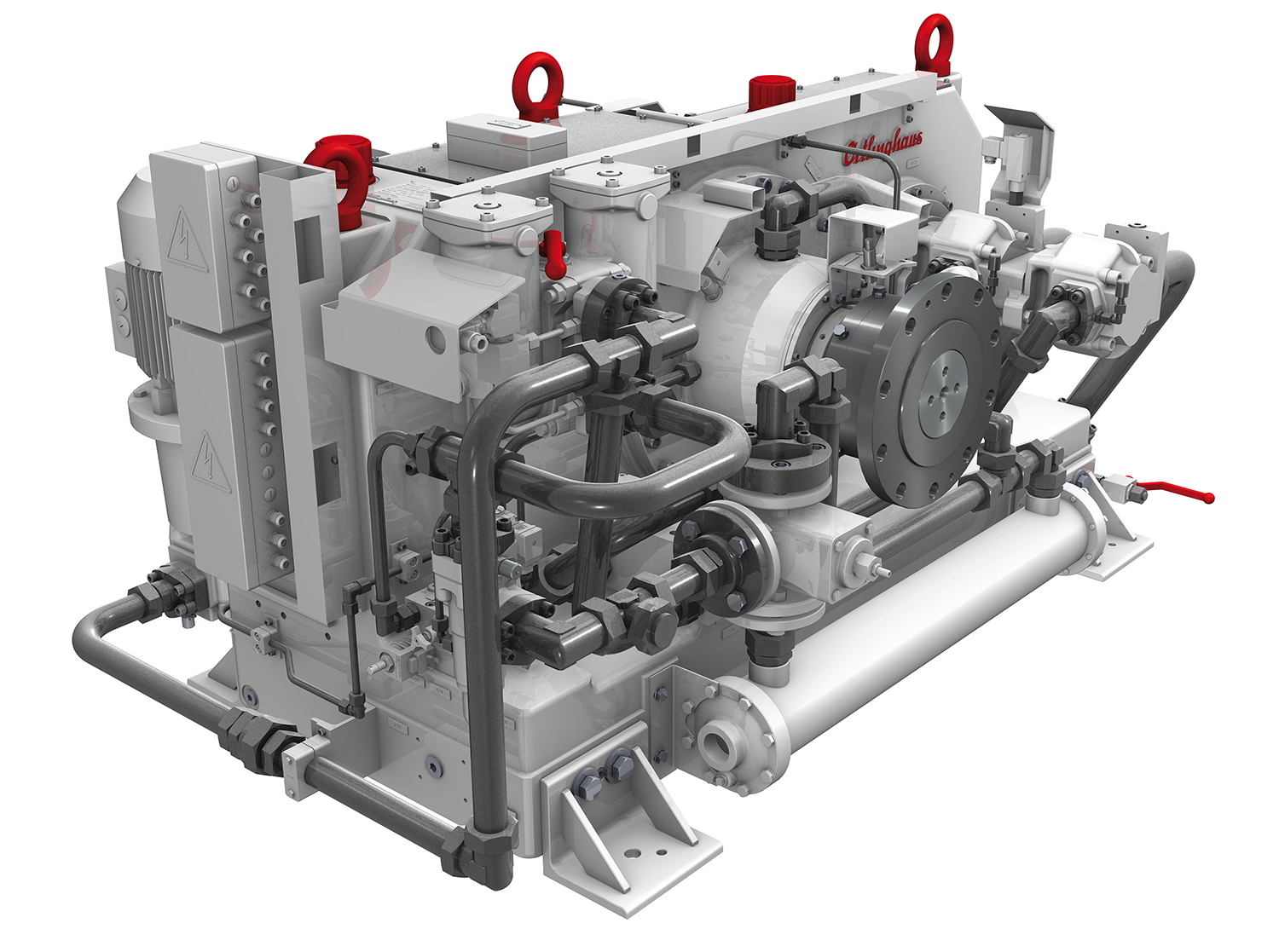

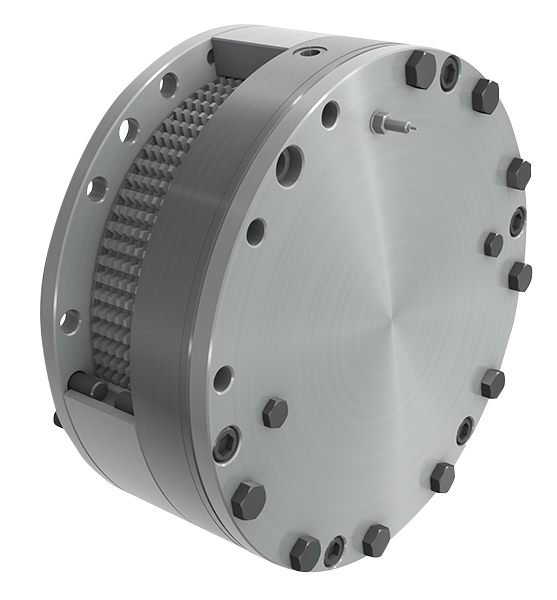

Hydraulical brake | Series 022 | Hydraulical brake | Series 022The 022 series is one of the most successful Ortlinghaus products. Well over one million units are in service around the world wherever safety brakes with an extremely long service life and quality without compromise are required. In marine engineering, these multi-plate brakes are used in the deck machinery sector and as shaft brakes. The advantage of these wet-running, hydraulically released and spring-applied multi-plate brakes is the high torques they achieve in compact dimensions. Hydraulically actuated brakes are also available as a special version. The spring-loaded brakes are safety brakes, which automatically work in cases of pressure failure. The brakes can achieve full torque even when there is no pressure.

|

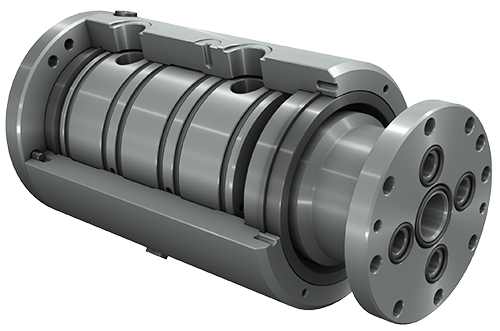

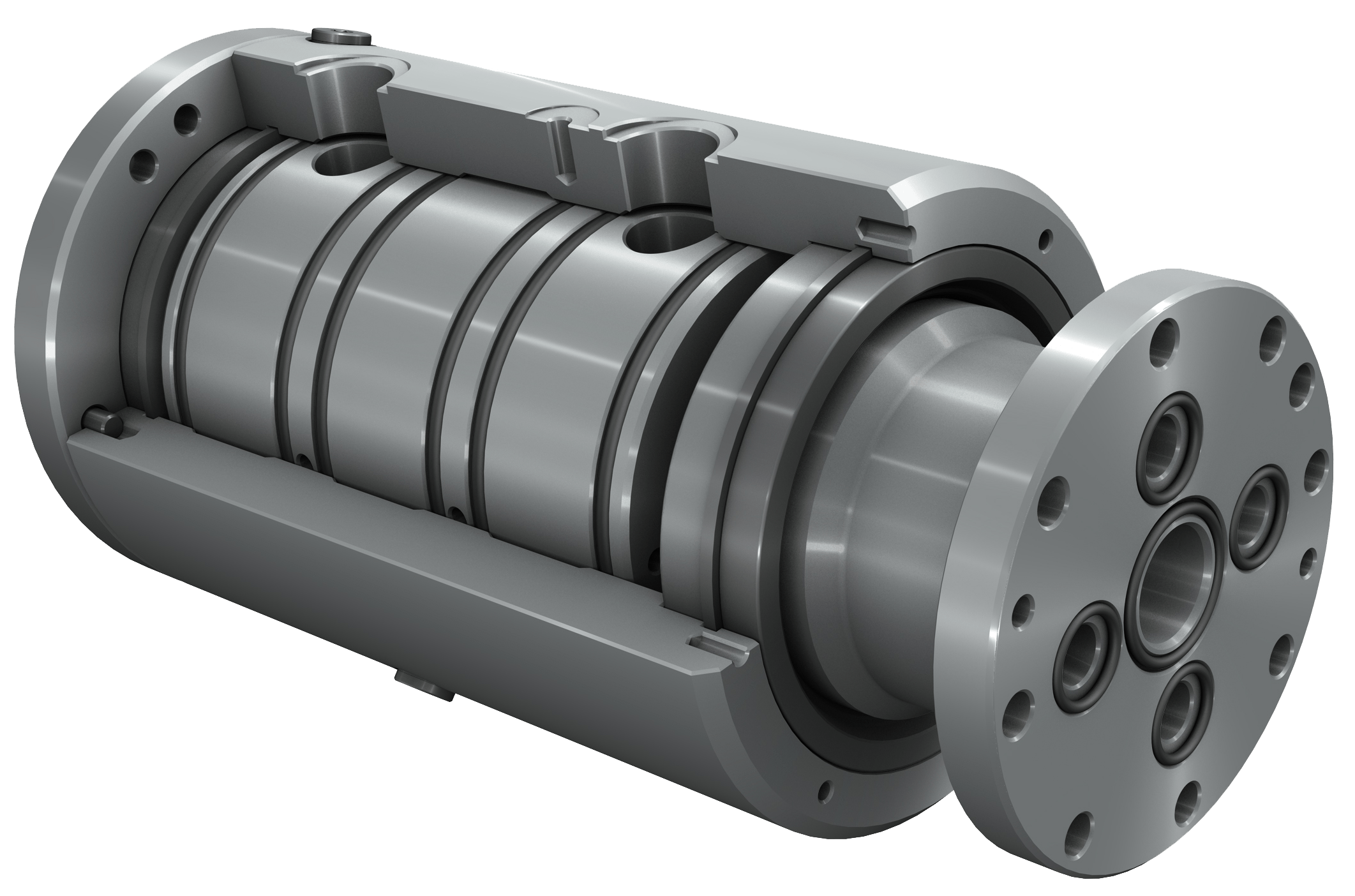

Oil inlet | Oil inletOrtlinghaus has been manufacturing single and multi-channel rotary inlets for several decades and these are frequently supplied as accessories for oil actuated and also for oil cooled clutches. These tried and tested machine components for the feeding of pressurised oil and cooling oil into rotating shafts are standard products.In addition to this Ortlinghaus also develops and manufactures rotary inlets to customers own requirements, which are not listed in the catalogue of our standard products. It is thus possible for example to manufacture rotary inlets with more than three channels. The oil inlets are available in axial and radial variants.

|