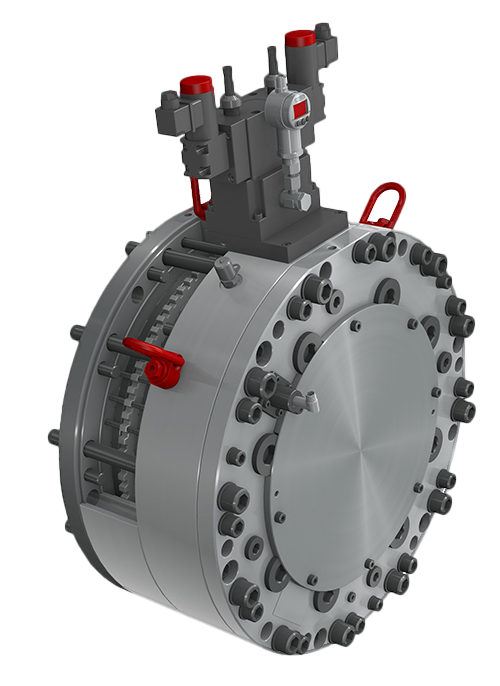

Ortlinghaus has been the first with a specific safety brake. solution for the field of servo presses. After more than 10 years of experience, we have launched the new Prot.act generation series 172 which fulfills highest safety and customer requirements for this application.

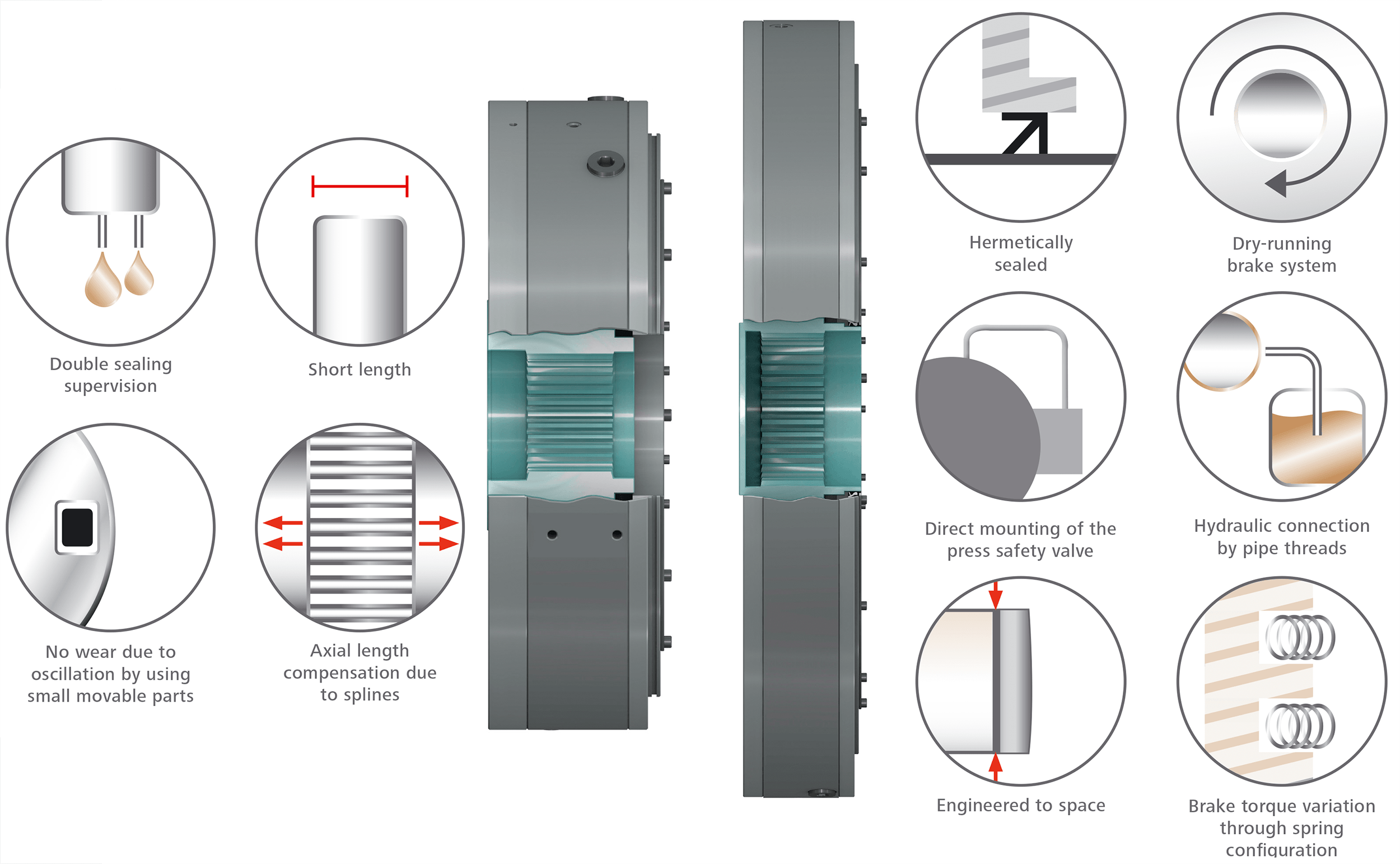

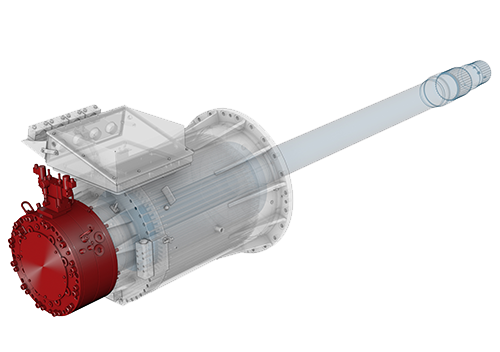

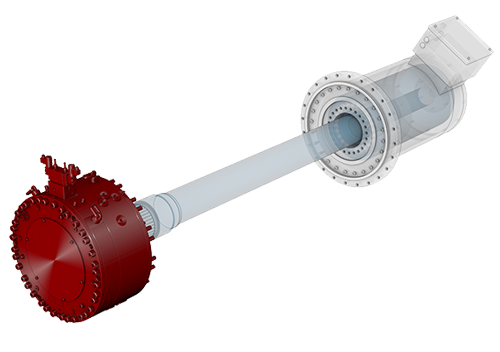

The Prot.act brake is specifically designed for servomotordriven presses and is used as ram holding and as emergency brake. It fulfills the requirements according DIN EN ISO 16092 as a safety brake, and stops the ram in emergency cases in shortest time (e.g. the event of a power failure).

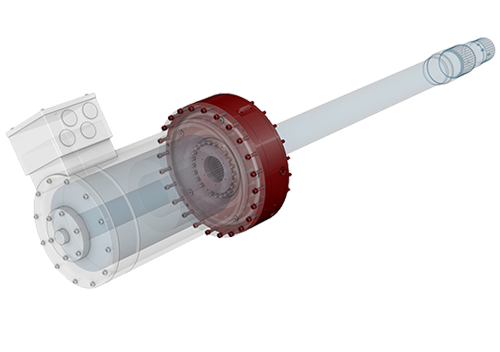

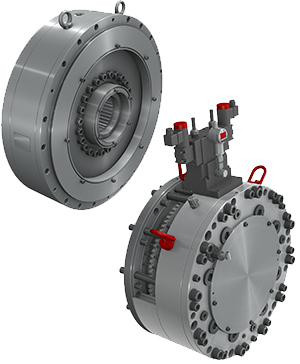

The brake is characterized by its minimal space requirements, low moment of inertia of the parts rotating with the drive motor, and short engagement times. Thanks to its enclosed design, the brake also produces only a very low external pollution and with a minimal noise level. It conforms to the European safety standard DIN EN ISO 16092 and is largely maintenance-free.

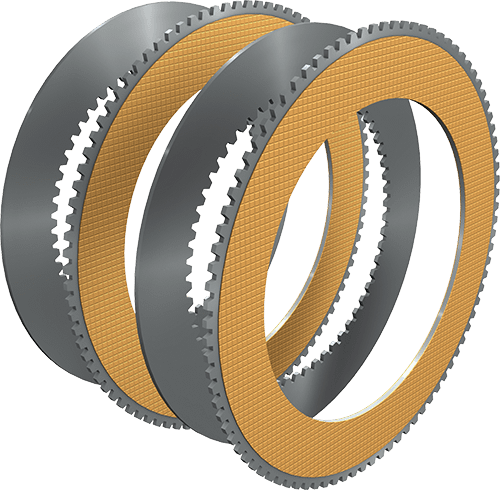

Due to friction block design, the axial mobility of the friction elements when operating the brake is possible without moving metallic contact points. On this way fretting corrosion is prevented. Thanks to the dry-running principle, no undesired residual torque develops during normal operation of the press with the brake open.

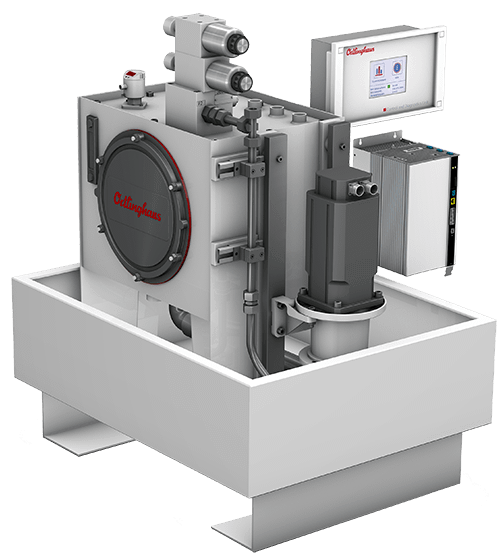

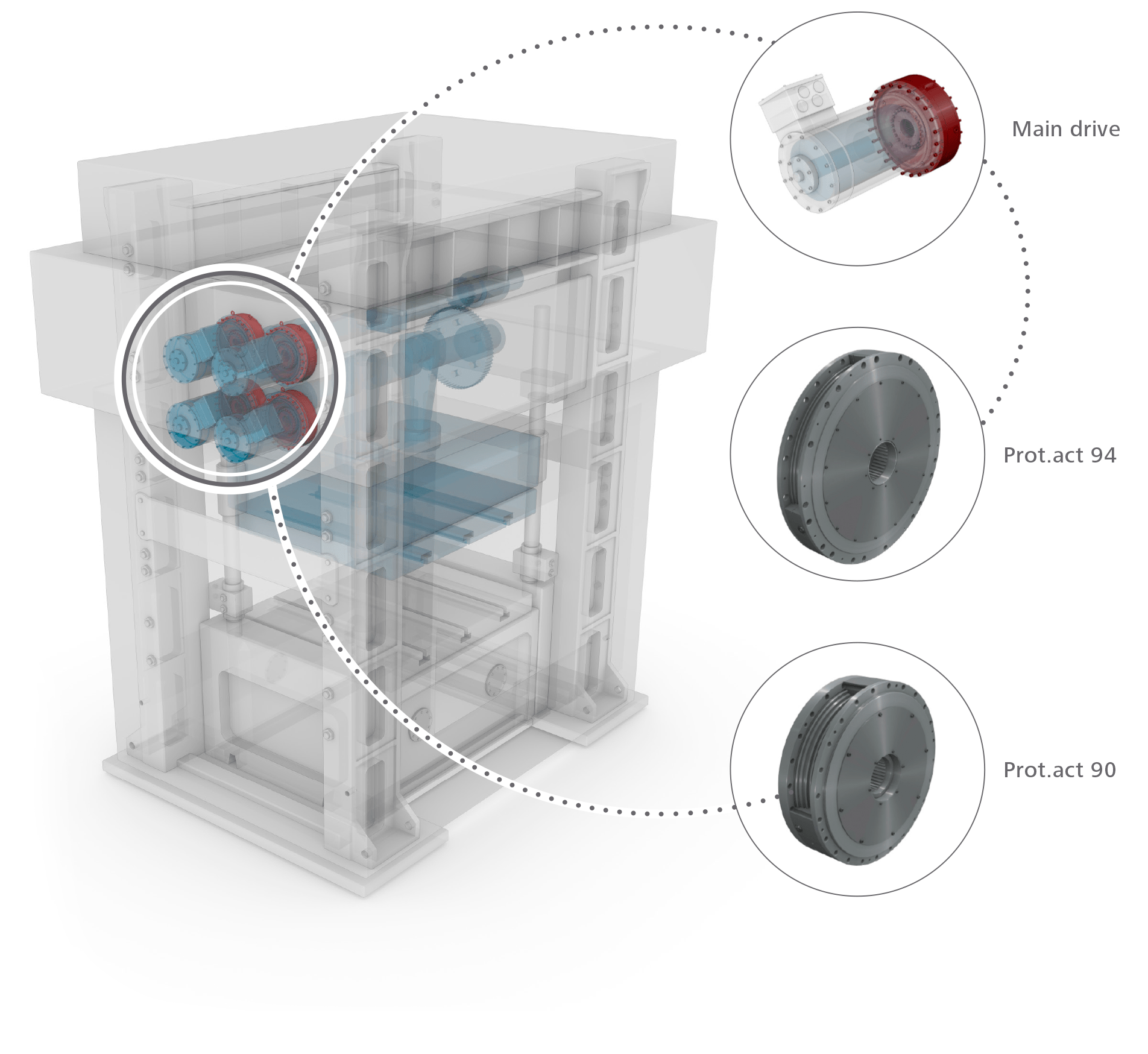

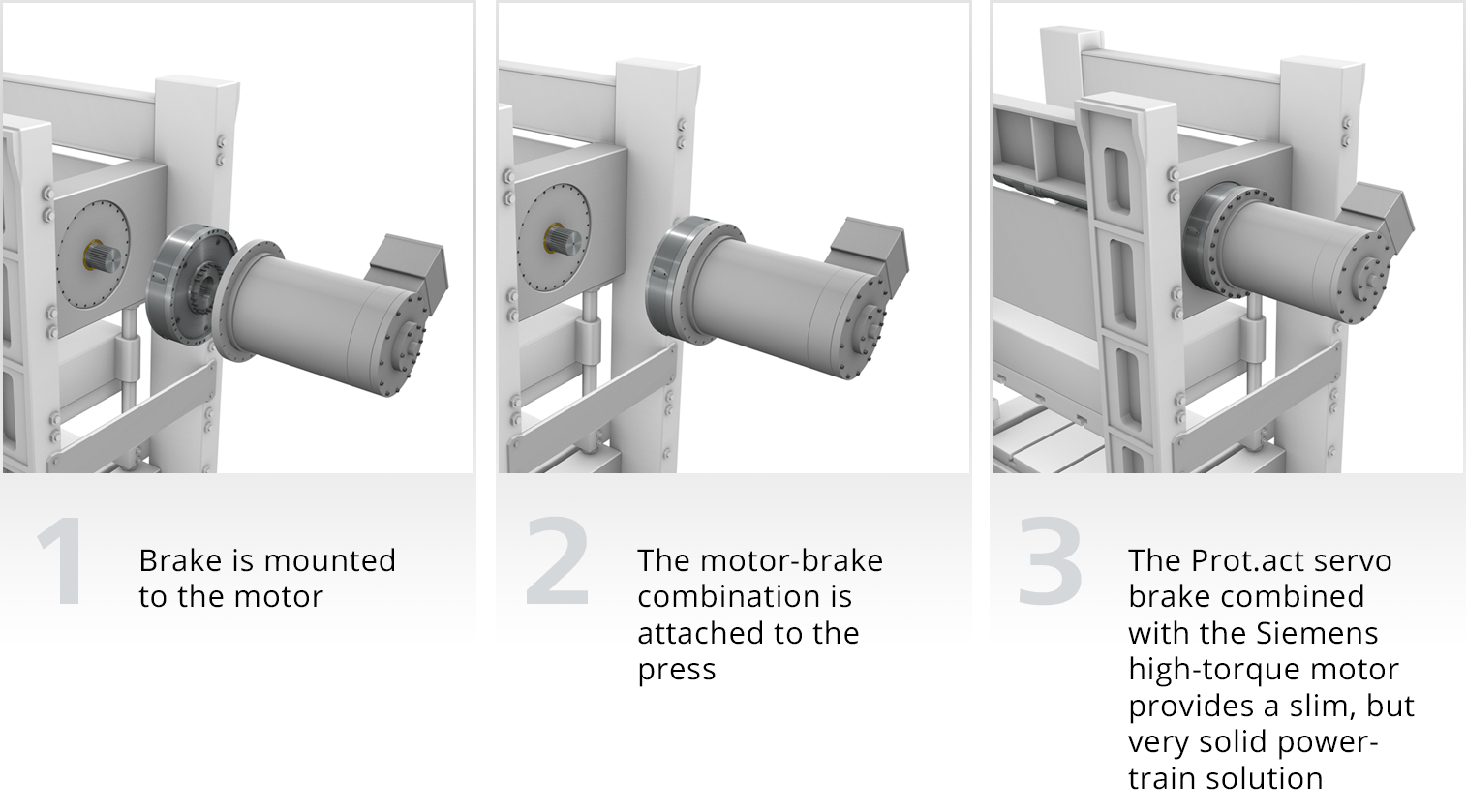

The Prot.act servo is also available in two sizes that are designed for integration in front of the Siemens high-torque motors 1FW3 and 1FW4. The Prot.act flange dimensions in size 90 and 94 if this series are exactly the same as the Siemens motor flanges, which allows a slim but compact and robust drivetrain concept.

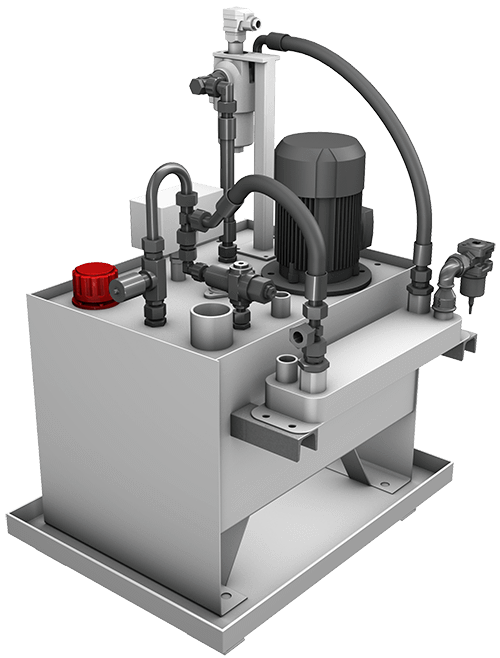

Prot.act – Hydraulically released brake | Series 171 & 172. Ortlinghaus Quality.

|

Prot.actHydraulically released brake Prot.act |

Easy assembly and mounting.

Prot.act