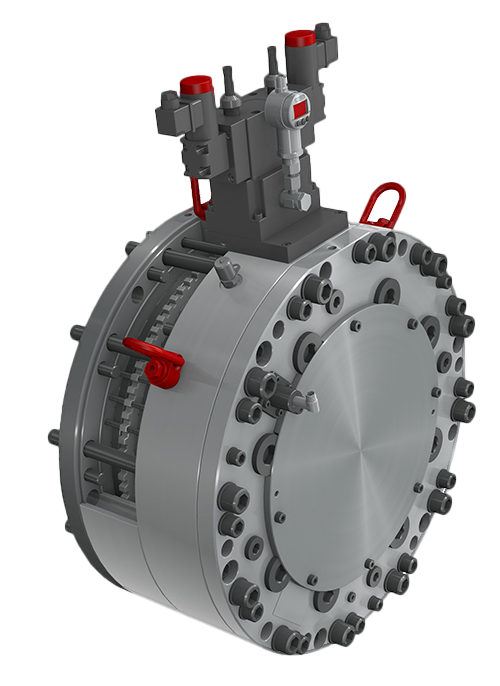

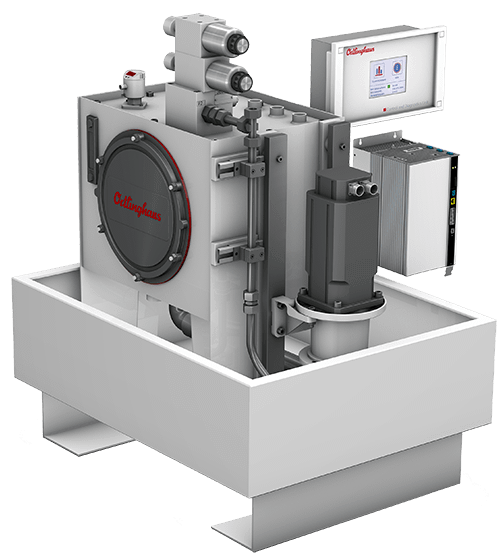

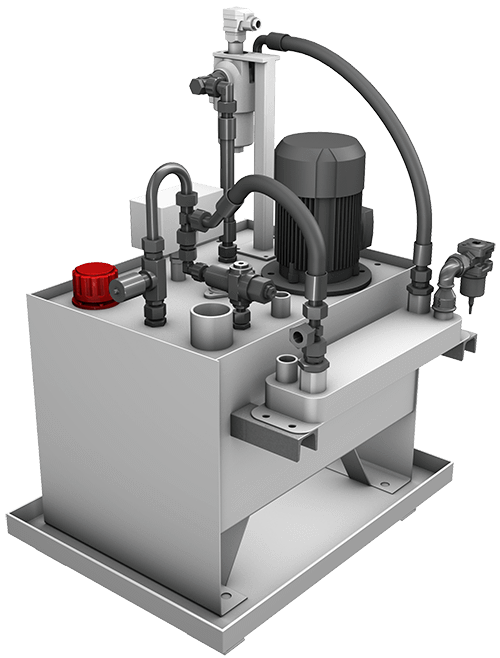

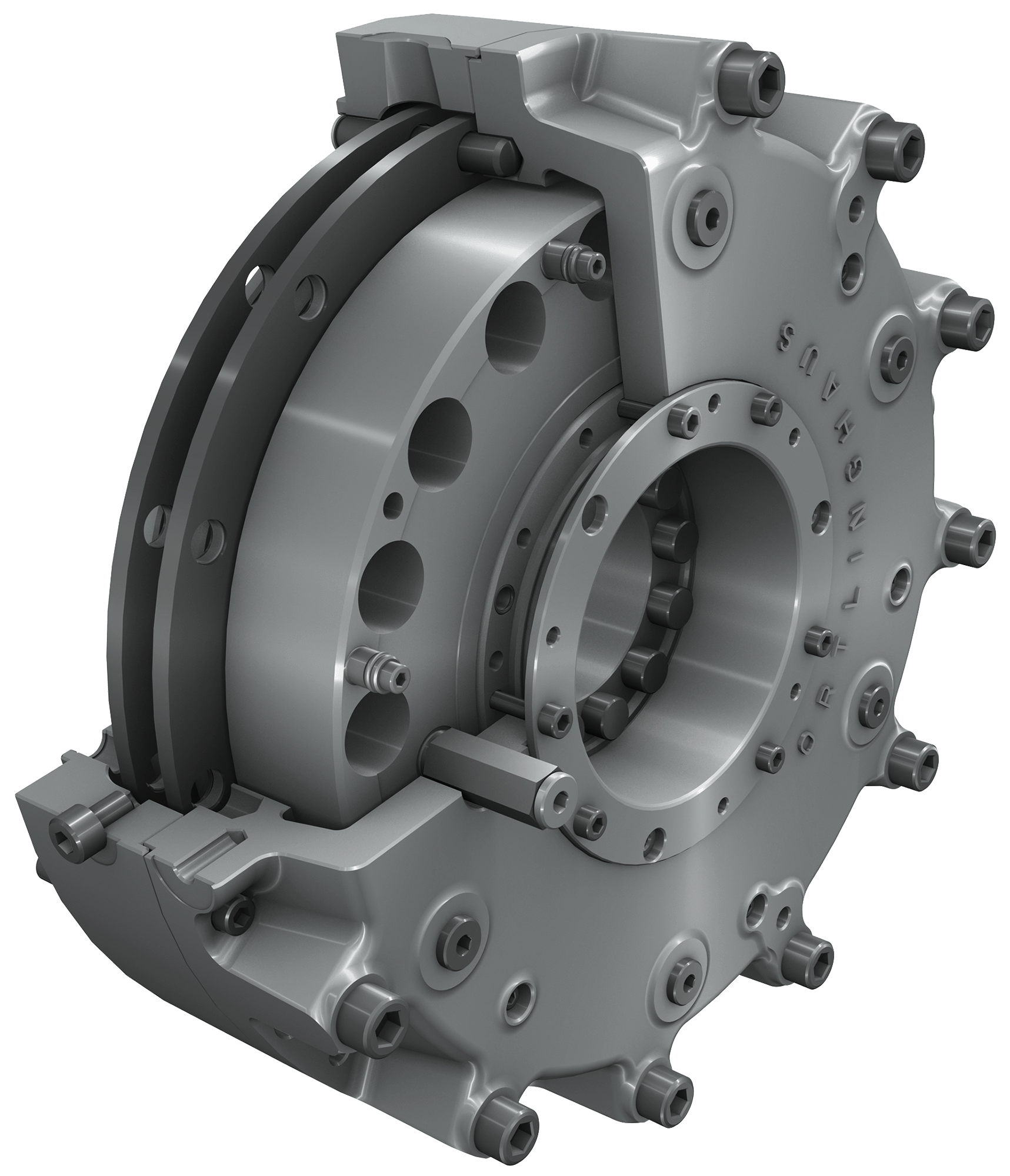

With the 170 model series, Ortlinghaus has developed a hydraulically released and spring-loaded brake with dry-running friction elements specifically developed for servomotor-driven presses. The brake is normally used as a holding brake for stationary machines, but can also be used as a safety brake for emergency stops.

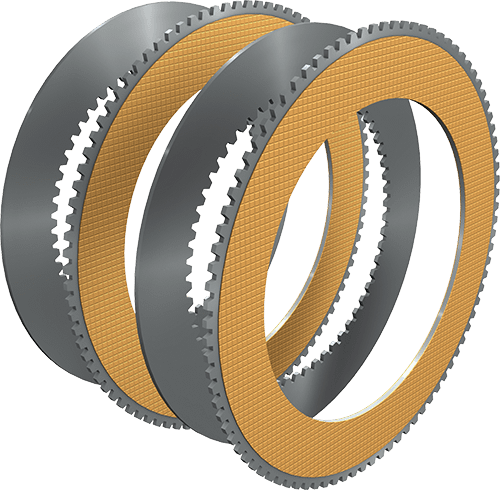

The brake is characterized by its minimal space requirements, low moment of inertia of the parts rotating with the drive motor, and short switching times. Designed as a multi-disc brake, it can transfer high torque. Thanks to its enclosed design, the brake also operates with low external pollution and minimal noise. It conforms to the European safety standard DIN EN ISO 16092 and is largely maintenance-free.

Due to the design format with friction pads, the axial mobility of the friction elements when operating the brake is possible without moving metallic contact points. Thanks to the dry-running principle, no undesired residual torque develops during normal operation of the press with the brake open.